Routing (electronic design automation)

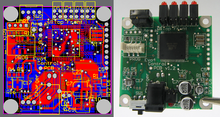

It builds on a preceding step, called placement, which determines the location of each active element of an IC or component on a PCB.

After placement, the routing step adds wires needed to properly connect the placed components while obeying all design rules for the IC.

This introduces many additional complications not faced by routers for other applications such as printed circuit board or multi-chip module design.

Modern PCB design software typically provides "interactive routers"—the drafter selects a pad and clicks a few places to give the EDA tool an idea of where to go, and the EDA tool tries to place wires as close to that path as possible without violating design rule checking (DRC).

Modern PCB design software also typically provides "autorouters" that route all remaining unrouted connections without human intervention.

Restricted directions make power supply design and the control of inter-layer crosstalk easier, but allowing arbitrary routes can reduce the need for vias and decrease the number of required wiring layers.