Aggregated diamond nanorod

Nanodiamond or hyperdiamond was produced by compression of graphite in 2003 by a group of researchers in Japan and in the same work, published in Nature, it was shown to be much harder than bulk diamond.

[2] Later, it was also produced by compression of fullerene and confirmed to be the hardest and least compressible known material, with an isothermal bulk modulus of 491 gigapascals (GPa), while a conventional diamond has a modulus of 442–446 GPa; these results were inferred from X-ray diffraction data, which also indicated that ADNRs are 0.3% denser than regular diamond.

[3] The same group later described ADNRs as "having a hardness and Young's modulus comparable to that of natural diamond, but with 'superior wear resistance'".

ADNRs (hyperdiamonds/nanodiamonds) are produced by compressing fullerite powder—a solid form of allotropic carbon fullerene—by either of two somewhat similar methods.

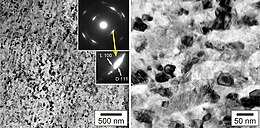

[5][6] The material is a series of interconnected diamond nanorods, with diameters of between 5 and 20 nanometres and lengths of around 1 micrometre each.