Carbide-derived carbon

[9] This ability to precisely tune the size and shapes of pores makes CDCs attractive for selective sorption and storage of liquids and gases (e.g., hydrogen, methane, CO2) and the high electric conductivity and electrochemical stability allows these structures to be effectively implemented in electrical energy storage and capacitive water desalinization.

The production of SiCl4 by high temperature reaction of chlorine gas with silicon carbide was first patented in 1918 by Otis Hutchins,[10] with the process further optimized for higher yields in 1956.

[11] The solid porous carbon product was initially regarded as a waste byproduct until its properties and potential applications were investigated in more detail in 1959 by Walter Mohun.

Most commonly, dry chlorine treatment is used to selectively etch metal or metalloid atoms from the carbide precursor lattice.

It has been shown that the initial crystal structure of the carbide is the primary factor affecting the CDC porosity, especially for low-temperature chlorine treatment.

In particular, vertically aligned carbon nanotubes films of high tube density have been reported for vacuum decomposition of SiC.

The ability to produce a usable porous carbon material is dependent on the solubility of the formed metal oxide (such as SiO2) in supercritical water.

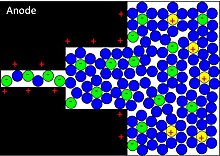

[18][26] One application of carbide-derived carbons is as active material in electrodes for electric double layer capacitors which have become commonly known as supercapacitors or ultracapacitors.

This is motivated by their good electrical conductivity combined with high surface area,[27] large micropore volume,[20] and pore size control[28] that enable to match the porosity metrics of the porous carbon electrode to a certain electrolyte.

[29] The highest capacitance values are observed for matching ion/pore systems, which allow high-density packing of ions in pores in superionic states.

[34] However, small pores, especially when combined with an overall large particle diameter, impose an additional diffusion limitation on the ion mobility during charge/discharge cycling.

SiOC-CDC with large subnanometer pore volumes are able to store over 5.5 wt.% hydrogen at 60 bar and −196 °C, almost reaching the goal of the US Department of Energy of 6 wt.% storage density for automotive applications.

[38] CDC films obtained by vacuum annealing (ESK) or chlorine treatment of SiC ceramics yield a low friction coefficient.

The friction coefficient of SiC, which is widely used in tribological applications for its high mechanical strength and hardness, can therefore decrease from ~0.7 to ~0.2 or less under dry conditions.

The porous 3-dimensional network of CDC allows for high ductility and an increased mechanical strength, minimizing fracture of the film under an applied force.

These are the most common receptor-binding agents released into the body during a bacterial infection that cause the primary inflammatory response during the attack and increase the potential lethality of sepsis, making their removal a very important concern.

[45] Having originated as the by-product of industrial metal chloride synthesis, CDC has certainly a potential for large-scale production at a moderate cost.