Hex key

Hex keys are formed from a single piece of hard hexagonal steel rod, having blunt ends that fit snugly into similarly shaped screw sockets.

P. L. Robertson of Milton, Ontario, first commercialized the square socket in 1908, having perfected and patented a suitable cold forming method, using the right material and the right die design.

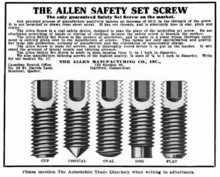

The headless set screws would be less likely to catch the clothing of workers and pull them into injurious contact with the running shaft.

SPS at the time was a prominent maker of shaft hangers and collars, the latter of which were put in place with set screws.

"[6] Hallowell does not elaborate on why SPS found that the square hole "would not be acceptable in this country", but it seems likely that it would have to have involved licensing Robertson's patent, which would have defeated SPS's purpose of driving down its cost for internal-wrenching screws (and may have been unavailable at any price, as explained at "List of screw drives > Robertson").

The story, if any, of whether SPS's methods required licensing of Allen's 1910 patent is not addressed by Hallowell's memoir.

World War II, with its unprecedented push for industrial production of every kind, is probably the event that first put most laypersons in contact with the internal-wrenching hexagon drive.

(Popular Science magazine would note in 1946 "Cap screws and setscrews with heads recessed to take hexagonal-bar wrenches are coming into increasing use.

[10][11][12] Hex keys with the INBUS brand are now manufactured at HaFu Werkzeugfabrik H. J. Fuhrmann GmbH, Breckerfeld, North Rhine-Westphalia, as of 2017 accounting for 7% of the company's EUR 8 million turnover[13] and as "Unbrako" key or wrench in Scandinavia (originally a Pennsylvania company established in 1911, in 2008 acquired by Deepak Fasteners Limited).

Hex keys are measured across-flats (AF), which is the distance between two opposite (parallel) sides of the hexagon.

While providing access to otherwise inaccessible screws, thinning of the tool shaft to create the rounded shape renders it weaker than the straight-shaft version, limiting the torque that can be applied; in addition, the rounded end only makes point contact with the screw as opposed to the line contact made by straight-shaft keys.

Hex keys are made by imparting the hexagon cross-section to steel wire (for example, with a drawing die), then bending and shearing.