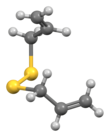

Diallyl disulfide

In 1844, Theodor Wertheim separated by steam distillation a pungent-smelling substance from garlic and named it "allyl sulfur."

The natural precursor of diallyl disulfide, allicin, was discovered in 1944 by Chester J. Cavallito and John Hays Bailey.

In 1947, A. Stoll and E. Seebeck found that allicin in turn can be produced from the cysteine derivative alliin using the enzyme alliinase.

[3][4] Diallyl disulfide and the related trisulfide are produced by decomposition of allicin, which is released upon breaking the cells of the Alliaceae plants, especially garlic.

It is a clear, yellowish liquid which boils at 138–139 °C (for the typical 80% purity) and has its flash point at 50 °C, a density of about 1.0 g/mL and a vapor pressure of 1 mmHg at 20 °C.

[1][14] The unpleasant smell of diallyl disulfide is perceived through the transient receptor potential cation channel, member A1 (TRPA1).

It significantly increases the production of the enzyme glutathione S-transferase (GST), which binds electrophilic toxins in the cell.

This was confirmed in a study on rats where prolonged administration of diallyl disulfide protected poisoning of their intestinal cells.

This study also showed that certain side effects of high doses of garlic oil are not attributable to the diallyl disulfide.

[29][30] Because of its antimicrobial effects, diallyl disulfide, together with tobramycin, is included in preparations which are used for selective decontamination of the organs (e.g. gut) before surgical operations.

[31] Garlic can prevent colorectal cancer,[32] and several studies revealed that diallyl disulfide is a major component responsible for this action.

[35] It also results in a strong and dose-dependent accumulation of several agents, such as reactive oxygen species, which activate enzyme and lead to destruction of cancer cells.