Differential pulley

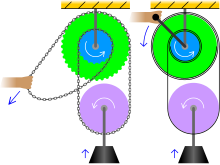

It is operated by pulling upon the slack section of a continuous chain that wraps around two pulleys on a common shaft.

The relative sizing of the two connected pulleys determines the maximum weight that can be lifted by hand.

If the pulley radii are close enough, then the load will remain in place (and not lower under the force of gravity) until the chain is pulled.

[1] The differential pulley was invented in 1854 by Thomas Aldridge Weston from King's Norton, England.

According to Richard Tangye's autobiography, the Weston differential pulley evolved from the Chinese windlass, with an endless chain replacing the finite length of rope.

This factor (the mechanical advantage MA) depends on the relative difference of the radii r and R of the connected pulleys: The effect on the forces and distances (see figure) is quantitatively: The difference in radii can be made very small, making the mechanical advantage of this pulley system very large.

A much simpler method of calculating mechanical advantage can be accomplished by simply counting and comparing the chain link pockets in the two differentially-sized sprockets.