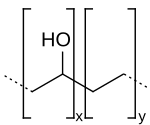

Ethylene vinyl alcohol

Because the latter monomer mainly exists as its tautomer acetaldehyde, the copolymer is prepared by polymerization of ethylene and vinyl acetate to give the ethylene vinyl acetate (EVA) copolymer followed by hydrolysis.

Instead of making an entire package out of EVOH, manufacturers keep costs down by coextruding or laminating it as a thin layer between cardboard, foil, or other plastics.

It has production sites in Mizushima, Japan; La Porte, Texas in the USA; and at Salt End, Hull, England.

Due to its strong barrier against gasses (especially oxygen), odors and flavours,[5] food packaging manufacturers use EVOH in their packaging structure to extend the shelf life of food products.

[8] Dissolved in dimethyl sulfoxide (DMSO) and mixed with a radiopaque substance, ethylene vinyl alcohol copolymer is used to embolize blood vessels.