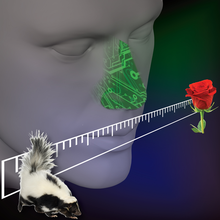

Electronic nose

Since 1982,[2] research has been conducted to develop technologies, commonly referred to as electronic noses, that could detect and recognize odors and flavors.

The stages of the recognition process are similar to human olfaction and are performed for identification, comparison, quantification and other applications, including data storage and retrieval.

[6] The electronic nose was developed in order to mimic human olfaction that functions as a non-separative mechanism: i.e. an odor / flavor is perceived as a global fingerprint.

[11] Bio-electronic noses use olfactory receptors – proteins cloned from biological organisms, e.g. humans, that bind to specific odor molecules.

[17] Studies of airflow around canine noses, and tests on lifesize models have indicated that a cyclic 'sniffing action' similar to that of a real dog is beneficial in terms of improved range and speed of response[18] In recent years, other types of electronic noses have been developed that utilize mass spectrometry or ultra-fast gas chromatography as a detection system.

This part of the instrument performs global fingerprint analysis and provides results and representations that can be easily interpreted.

These systems include artificial neural network (ANN),[19] fuzzy logic, chemometrics methods,[20] pattern recognition modules, etc.

Various application notes describe analysis in areas such as flavor and fragrance, food and beverage, packaging, pharmaceutical, cosmetic and perfumes, and chemical companies.

[46][47] Since emission rates on a site can be extremely variable for some sources, the electronic nose can provide a tool to track fluctuations and trends and assess the situation in real time.

Real time modeling will present the current situation, allowing the operator to understand which periods and conditions are putting the facility at risk.