Firebox (steam engine)

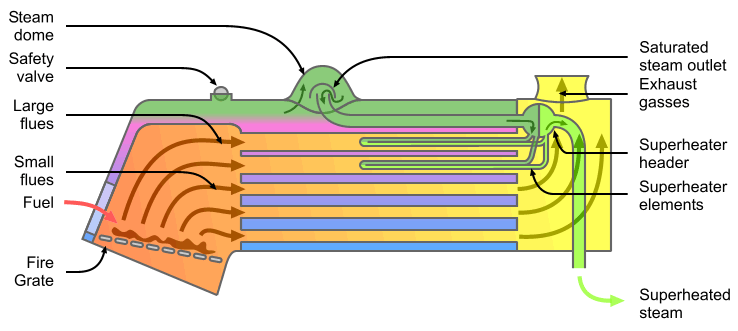

In a steam engine, the firebox is the area where the fuel is burned, producing heat to boil the water in the boiler.

The hot gases generated in the firebox are pulled through a rack of tubes running through the boiler.

[1][2] In the standard steam locomotive fire-tube boiler, the firebox is surrounded by water space on five sides.

If the engine burns solid fuel, like wood or coal, there is a grate covering most of the bottom of the firebox to hold the fire.

Wood ash is generally powder which will fall through the grates with no more agitation required than the vibrations of the locomotive rolling down the track.

Instead, they have a heavy metal gauge firing pan bolted tight against the bottom of the firebox.

The brick arch directs heat, flames, and smoke back over the fire towards the rear of the firebox.

The invention of the brick arch allowed locomotives to burn cheaper coal (which contains volatiles) instead of coke, it having been a legal requirement from the outset for engines to "consume their own smoke".

The fusible plugs, usually located in the highest part of the crown sheet, have a soft metal alloy core which melts out if the water level in the boiler gets too low.

This arrangement gives the firebox end of the boiler a more square shape and is usually made as large as possible within the loading gauge, to offer the greatest heating surface where the fire is hottest.

Steam is usually collected at the front corners of a Belpaire firebox, allowing for a domeless boiler.

The top of the firebox, rather than being horizontal, is visibly higher at the front than at the rear to reduce the risk of water being carried over with the steam.

The Wootten firebox was very tall and wide to allow combustion of anthracite coal waste.

Buildup of soot and scale can also lead to overheating and subsequent tube failure if not cleaned properly to remove soot (with water, compressed air and cleaning rods) and scale with boiler washouts and water treatment e.g. Porta Treatment (minimizes and virtually prevents scale buildup) is named after the Argentine locomotive engineer Livio Dante Porta, who invented it.

The fireman also assists the driver by spotting signals and keeping a good look out when not attending to the boiler.