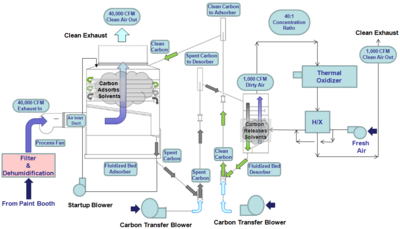

Fluidized bed concentrator

The system uses a bed of activated carbon beads to adsorb volatile organic compounds (VOCs) from the exhaust gas.

The fluidized bed concentrator consists of five primary components: Industrial processes requiring ventilation, including paint booths,[2] printing, and chemical production, exhaust the ventilated air to the fluidized bed concentrator at room temperature.

[3] The air first passes into the adsorption tower, where it moves through six perforated trays of clean carbon beads.

In some cases, small amounts of carbon monoxide (CO), nitrogen oxide (NOX), and other gases are produced.

Despite an increase in Line 2 production, Honda is realizing a reduction in plant VOC emissions of nearly 60 metric tons annually as a result of the installation of the FBC system.