Adsorption

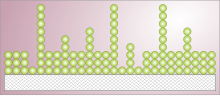

adsorption: An increase in the concentration of a dissolved substance at the interface of a condensed and a liquid phase due to the operation of surface forces.

[8] Adsorption is present in many natural, physical, biological and chemical systems and is widely used in industrial applications such as heterogeneous catalysts,[9][10] activated charcoal, capturing and using waste heat to provide cold water for air conditioning and other process requirements (adsorption chillers), synthetic resins, increasing storage capacity of carbide-derived carbons and water purification.

[11] Adsorption, ion exchange and chromatography are sorption processes in which certain adsorbates are selectively transferred from the fluid phase to the surface of insoluble, rigid particles suspended in a vessel or packed in a column.

Pharmaceutical industry applications, which use adsorption as a means to prolong neurological exposure to specific drugs or parts thereof,[citation needed] are lesser known.

[13] The first mathematical fit to an isotherm was published by Freundlich and Kuster (1906) and is a purely empirical formula for gaseous adsorbates: where

change to reflect the empirical observation that the quantity adsorbed rises more slowly and higher pressures are required to saturate the surface.

It is the most common isotherm equation to use due to its simplicity and its ability to fit a variety of adsorption data.

The fourth condition is the most troublesome, as frequently more molecules will adsorb to the monolayer; this problem is addressed by the BET isotherm for relatively flat (non-microporous) surfaces.

Advances in computational power allowed for nonlinear regression to be performed quickly and with higher confidence since no data transformation is required.

In 1938 Stephen Brunauer, Paul Emmett, and Edward Teller developed a model isotherm that takes that possibility into account.

Further simulations and analysis of this equation[19] show that the square root dependence on the time is originated from the decrease of the concentrations near the surface under ideal adsorption conditions.

Correction on the reduction of the adsorption area and slowing down of the concentration gradient evolution have to be considered over a longer time.

Empirically, this plot was noticed as being a very good fit to the isotherm by Michael Polanyi[22][23][24] and also by Jan Hendrik de Boer and Cornelis Zwikker[25] but not pursued.

[26] Most industrial adsorbents fall into one of three classes: Silica gel is a chemically inert, non-toxic, polar and dimensionally stable (< 400 °C or 750 °F) amorphous form of SiO2.

Zeolites are natural or synthetic crystalline aluminosilicates, which have a repeating pore network and release water at high temperature.

This high temperature heat treatment breaks the aluminum-oxygen bonds and the aluminum atom is expelled from the zeolite framework.

[28] Activated carbon is a highly porous, amorphous solid consisting of microcrystallites with a graphite lattice, usually prepared in small pellets or a powder.

One of its main drawbacks is that it reacts with oxygen at moderate temperatures (over 300 °C).Activated carbon can be manufactured from carbonaceous material, including coal (bituminous, subbituminous, and lignite), peat, wood, or nutshells (e.g., coconut).

The most popular aqueous phase carbons are bituminous based because of their hardness, abrasion resistance, pore size distribution, and low cost, but their effectiveness needs to be tested in each application to determine the optimal product.

Recent research works reported activated carbon as an effective agent to adsorb cationic species of toxic metals from multi-pollutant systems and also proposed possible adsorption mechanisms with supporting evidences.

For chemically adsorbed water, hydration may be in the form of either dissociative adsorption, where H2O molecules are dissociated into surface adsorbed -H and -OH, or molecular adsorption (associative adsorption) where individual water molecules remain intact [34] The low cost ($200/ton) and high cycle rate (2,000 ×) of synthetic zeolites such as Linde 13X with water adsorbate has garnered much academic and commercial interest recently for use for thermal energy storage (TES), specifically of low-grade solar and waste heat.

Typically, hot dry air from flat plate solar collectors is made to flow through a bed of zeolite such that any water adsorbate present is driven off.

Storage can be diurnal, weekly, monthly, or even seasonal depending on the volume of the zeolite and the area of the solar thermal panels.

The adsorption chamber of the chiller is filled with a solid material (for example zeolite, silica gel, alumina, active carbon or certain types of metal salts), which in its neutral state has adsorbed the refrigerant.

The phenomenon relies on the common "spillover" effect (described below), where certain adsorbed species exhibit high mobility on some surfaces.

[46] A similar, but independent model was developed by King and co-workers[47][48][49] to describe hydrogen adsorption on silica-supported alkali promoted ruthenium, silver-ruthenium and copper-ruthenium bimetallic catalysts.

[50] Zupanc et al. (2002) subsequently confirmed the same model for hydrogen adsorption on magnesia-supported caesium-ruthenium bimetallic catalysts.

[51] Trens et al. (2009) have similarly described CO surface diffusion on carbon-supported Pt particles of varying morphology.

[53] Adsorption of molecules onto polymer surfaces is central to a number of applications, including development of non-stick coatings and in various biomedical devices.

Scientists have used Tetris blocks "as a proxy for molecules with a complex shape" and their "adsorption on a flat surface" for studying the thermodynamics of nanoparticles.