Graphite oxide

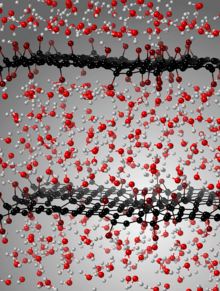

The maximally oxidized bulk product is a yellow solid with C:O ratio between 2.1 and 2.9, that retains the layer structure of graphite but with a much larger and irregular spacing.

[29] Cooling of Brodie graphite oxide immersed in excess of liquid methanol, ethanol, acetone and dimethylformamide results in step-like insertion of an additional solvent monolayer and lattice expansion.

The phase transition detected by X-ray diffraction and differential scanning calorimetry (DSC) is reversible; de-insertion of solvent monolayer is observed when sample is heated back from low temperatures.

[30] An additional methanol and ethanol monolayer is reversibly inserted into the structure of Brodie graphite oxide under high pressure conditions.

The interlayer distance of Hummers graphite oxide in an excess of liquid alcohols increases gradually upon temperature decrease, reaching 19.4 and 20.6 Å at 140 K for methanol and ethanol, respectively.

The gradual expansion of the Hummers graphite oxide lattice upon cooling corresponds to insertion of at least two additional solvent monolayers.

Graphene oxide sheets are chemically reactive in liquid water, leading them to acquire a small negative charge.

Also, the nonlinear refraction (Kerr effect) is crucial for applications including all-optical switching, signal regeneration, and fast optical communications.

Graphite oxide has attracted much interest as a possible route for the large-scale production and manipulation of graphene, a material with extraordinary electronic properties.

[56][57] Exposing a film of graphite oxide to the laser of a LightScribe DVD has also revealed to produce quality graphene at a low cost.

[60] Currently, researchers are focussed on reducing graphene oxide using non-toxic substances; tea and coffee powder, lemon extract and various plants based antioxidants are widely used.

[68] A composite consisting of NiFe2O4 small ferrimagnetic nanoparticles and partially reduced graphene oxide functionalized with nitrogen atoms was successfully used to remove Cr(III) ion from water.

[69] One project layered carbon atoms in a honeycomb structure, forming a hexagon-shaped crystal that measured about 0.1 millimeters in width and length, with subnanometer holes.

[72][better source needed] Layer-by-layer coatings based on amine-modified graphene oxide and Nafion show excellent antimicrobial performance that is not compromised when heated for 2 hours at 200 °C.

[74] Recently a group of researchers, from university of L'Aquila (Italy), discovered new wetting properties of graphene oxide thermally reduced in ultra-high vacuum up to 900 °C.

Graphene oxide-based composites functionalized with metal oxides and sulfides have been shown in recent research to induce enhanced battery performance.

Research in this field is developing, with additional exploration into methods involving nitrogen doping and pH adjustment to improve capacitance.

With the advances in micro- and nanofabrication techniques, continued miniaturization of the conventional optical lenses has always been requested for various applications such as communications, sensors, data storage and a wide range of other technology-driven and consumer-driven industries.

Specifically, ever smaller sizes, as well as thinner thicknesses of micro lenses, are highly needed for subwavelength optics or nano-optics with extremely small structures, particularly for visible and near-IR applications.

Also, as the distance scale for optical communications shrinks, the required feature sizes of micro lenses are rapidly pushed down.

Recently, the excellent properties of newly discovered graphene oxide provide novel solutions to overcome the challenges of current planar focusing devices.

Also, the linear optical absorption of GO is found to increase as the reduction of GO deepens, which results in transmission contrast between GO and rGO and therefore provides an amplitude modulation mechanism.

Finally, GO film offers flexible patterning capability by using the maskless DLW method, which reduces the manufacturing complexity and requirements.

Most importantly, the synthesized high quality GO thin films can be flexibly integrated on various substrates and easily manufactured by using the one-step DLW method over a large area at a comparable low cost and power (~nJ/pulse), which eventually makes the GO flat lenses promising for various practical applications.

The superior electron mobility and high surface area of graphene oxide sheets suggest it may be implemented as a catalyst that meets the requirements for this process.

Specifically, graphene oxide's compositional functional groups of epoxide (-O-) and hydroxide (-OH) allow for more flexible control in the water splitting process.

Recent research experiments have demonstrated that the photocatalytic activity of graphene oxide containing a band gap within the required limits has produced effective splitting results, particularly when used with 40-50% coverage at a 2:1 hydroxide:epoxide ratio.

When used in composite materials with CdS (a typical catalyst used in photocatalytic water splitting), graphene oxide nanocomposites have been shown to exhibit increased hydrogen production and quantum efficiency.

This hydrogen storage capability can be further manipulated by modulating the interlayer distance between sheets, as well as making changes to the pore sizes.

Graphene oxide has been studied for its promising uses in a wide variety of nanomedical applications including tissue engineering, cancer treatment, medical imaging, and drug delivery.