Shell (projectile)

[1] Shells are usually large-caliber projectiles fired by artillery, armoured fighting vehicles (e.g. tanks, assault guns, and mortar carriers), warships, and autocannons.

The shape is usually a cylinder topped by an ogive-tipped nose cone for good aerodynamic performance, and possibly with a tapered boat tail; but some specialized types differ widely.

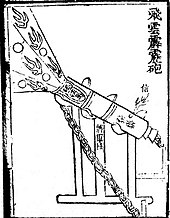

[2] The History of Jin 《金史》 (compiled by 1345) states that in 1232, as the Mongol general Subutai (1176–1248) descended on the Jin stronghold of Kaifeng, the defenders had a "thunder crash bomb" which "consisted of gunpowder put into an iron container ... then when the fuse was lit (and the projectile shot off) there was a great explosion the noise whereof was like thunder, audible for more than thirty miles, and the vegetation was scorched and blasted by the heat over an area of more than half a mou.

A hoard of several hundred ceramic grenades dated to the 17th century was discovered during building works in front of a bastion of the Bavarian city of Ingolstadt, Germany.

Martin von Wahrendorff and Joseph Whitworth independently produced rifled cannons in the 1840s, but it was Armstrong's gun that was first to see widespread use during the Crimean War.

This spin, together with the elimination of windage as a result of the tight fit, enabled the gun to achieve greater range and accuracy than existing smooth-bore muzzle-loaders with a smaller powder charge.

Progress was not possible until the discovery of mercury fulminate in 1800, leading to priming mixtures for small arms patented by the Rev Alexander Forsyth, and the copper percussion cap in 1818.

After one of the Austrian factories blew up in 1862, Thomas Prentice & Company began manufacturing guncotton in Stowmarket in 1863; and British War Office chemist Sir Frederick Abel began thorough research at Waltham Abbey Royal Gunpowder Mills leading to a manufacturing process that eliminated the impurities in nitrocellulose making it safer to produce and a stable product safer to handle.

Higher muzzle velocity meant a flatter trajectory and less wind drift and bullet drop, making 1000 meter shots practicable.

[18] The creation of cordite led to a lengthy court battle between Nobel, Maxim, and another inventor over alleged British patent infringement.

[22] Smoke balls also date back to the 17th century, British ones contained a mix of saltpetre, coal, pitch, tar, resin, sawdust, crude antimony and sulphur.

In 19th-century British service, they were made of concentric paper with a thickness about 1/15th of the total diameter and filled with powder, saltpeter, pitch, coal and tallow.

The case holds a set number of bagged charges and the gun crew can add or subtract propellant to change range and velocity.

Advantages include easier handling for larger caliber rounds, while range and velocity can easily be varied by increasing or decreasing the number of propellant charges.

Advantages include easier handling for large rounds, decreased metal usage, while range and velocity can be varied by using more or fewer propellant charges.

Gun calibers have standardized around a few common sizes, especially in the larger range, mainly due to the uniformity required for efficient military logistics.

In the shell, the cavity was slightly larger than in the shot and was filled with 1.5% gunpowder instead of being empty, to provide a small explosive effect after penetrating armour plating.

[25] However, ship armour rapidly improved during the 1880s and 1890s, and it was realised that explosive shells with steel had advantages including better fragmentation and resistance to the stresses of firing.

Although smokeless powders were used as a propellant, they could not be used as the substance for the explosive warhead, because shock sensitivity sometimes caused detonation in the artillery barrel at the time of firing.

Picric acid was the first high-explosive nitrated organic compound widely considered suitable to withstand the shock of firing in conventional artillery.

In 1885, based on research of Hermann Sprengel, French chemist Eugène Turpin patented the use of pressed and cast picric acid in blasting charges and artillery shells.

However, British researchers in that war identified 25% as being the optimal design for anti-personnel purposes, based on the recognition that far smaller fragments than hitherto would give a better effect.

The introduction of "insensitive munition" requirements, agreements and regulations in the 1990s caused modern western designs to use various types of plastic bonded explosives (PBX) based on RDX.

They were of cast or forged (three- and six-pounder) steel and contained a gunpowder bursting charge slightly smaller than that of a common shell, a trade off for the longer heavier nose.

By World War II they were superseded in Royal Navy service by common pointed capped (CPC) and semi-armour piercing (SAP), filled with TNT.

Shrapnel shells are an anti-personnel munition which delivered large numbers of bullets at ranges far greater than rifles or machine guns could attain – up to 6,500 yards by 1914.

Hence, it was replaced during World War I by the high-explosive shell, which exploded its fragments in all directions (and thus more difficult to avoid) and could be fired by high-angle weapons, such as howitzers.

Like cluster bombs, an artillery shell may be used to scatter smaller sub-munitions, including anti-personnel grenades, anti-tank top-attack munitions, and landmines.

They are not completely harmless: smoke and illumination shells can accidentally start fires, and impact by the discarded carrier of all three types can wound or kill personnel, or cause minor damage to property.

Blind shells often litter old battlefields; depending on the impact velocity, they may be buried some distance into the earth, all the while remaining potentially hazardous.

1 shell bursting charge

2 bullets

3 nose fuze

4 central ignition tube

5 resin matrix

6 thin steel shell wall

7 cartridge case

8 propellant