Liquefied natural gas

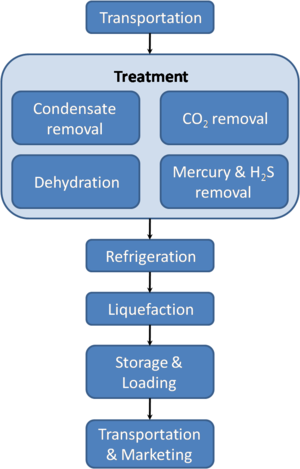

The liquefaction process involves removal of certain components, such as dust, acid gases, helium, water, and heavy hydrocarbons, which could cause difficulty downstream.

Developments of production processes, cryogenic storage, and transportation created the tools required to commercialize natural gas into a global market which now competes with other fuels.

These reserves of liquefied gas could be deployed at a moment's notice through regasification processes, and today are the main means for networks to handle local peak shaving requirements.

A number of scientists including Michael Faraday, James Joule, and William Thomson (Lord Kelvin) did experiments in this area.

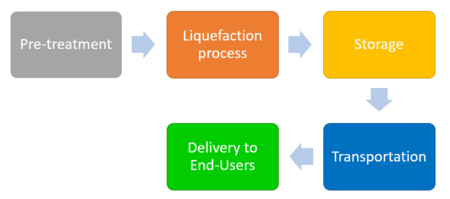

[11] The process begins with the pre-treatment of a feedstock of natural gas entering the system to remove impurities such as H2S, CO2, H2O, mercury and higher-chained hydrocarbons.

[12] The natural gas fed into the LNG plant will be treated to remove water, hydrogen sulfide, carbon dioxide, benzene and other components that will freeze under the low temperatures needed for storage or be destructive to the liquefaction facility.

In the early 2000s, prices for constructing LNG plants, receiving terminals and vessels fell as new technologies emerged and more players invested in liquefaction and regasification.

This tended to make LNG more competitive as a means of energy distribution, but increasing material costs and demand for construction contractors have put upward pressure on prices in the last few years.

When Korean and Chinese shipyards entered the race, increased competition reduced profit margins and improved efficiency—reducing costs by 60 percent.

Costs in US dollars also declined due to the devaluation of the currencies of the world's largest shipbuilders: the Japanese yen and Korean won.

Broadwater Energy, an effort of TransCanada Corp. and Shell, wishes to build an LNG import terminal in the sound on the New York side.

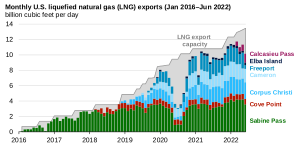

On September 13, 2013, the U.S. Department of Energy approved Dominion Cove Point's application to export up to 770 million cubic feet per day of LNG to countries that do not have a free trade agreement with the U.S.[26] In May 2014, the FERC concluded its environmental assessment of the Cove Point LNG project, which found that the proposed natural gas export project could be built and operated safely.

With low shipbuilding costs, and the buyers preferring to ensure reliable and stable supply, however, contracts with FOB terms increased.

Receiving terminals exist in about 40[34] countries, including Belgium, Chile, China, the Dominican Republic, France, Greece, India, Italy, Japan, Korea, Poland, Spain, Taiwan, the UK, the US, among others.

For large-scale transport uses, the LNG is typically regassified at the receiving end and pushed into the local natural gas pipeline infrastructure.

As of the end of first quarter of 2015, Prometheus Energy Group Inc claimed to have delivered over 100 million gallons of LNG to the industrial market within the previous four years[64] and is continuing to add new customers.

Feeder and short-sea shipping company Unifeeder has been operating the world's first LNG powered container vessel, the Wes Amelie, since late 2017, transiting between the port of Rotterdam and the Baltics on a weekly schedule.

[72][73] BHP, one of the largest mining companies in the world, is aiming to commission minerals transport ships powered with LNG by late 2021.

[87] In November 2021, U.S. producer Venture Global LNG signed a twenty-year contract with China's state-owned Sinopec to supply liquefied natural gas.

Much of this growth is driven by the need for clean fuel and some substitution effect due to the high price of oil (primarily in the heating and electricity generation sectors).

Japan, South Korea, Spain, France, Italy and Taiwan import large volumes of LNG due to their shortage of energy.

[citation needed] Following the Fukushima Daiichi nuclear disaster in March 2011 Japan became a major importer accounting for one third of the total.

The small-scale LNG plant also allows localized peakshaving to occur—balancing the availability of natural gas during high and low periods of demand.

It also makes it possible for communities without access to natural gas pipelines to install local distribution systems and have them supplied with stored LNG.

[112] LNG briefly touched the oil parity in winter of 2018/2019[113] and then rose above it during the recent global energy crisis in mid-2021[114] only falling below it in early 2024.

Large tanks are low aspect ratio (height to width) and cylindrical in design with a domed steel or concrete roof.

Natural gas will travel much faster than oil through a high-pressure pipeline, but can transmit only about a fifth of the amount of energy per day due to the lower density.

Natural gas could be considered the least environmentally harmful fossil fuel because it has the lowest CO2 emissions per unit of energy and is suitable for use in high efficiency combined cycle power stations.

However, on the West Coast of the United States, where up to three new LNG importation terminals were proposed before the U.S. fracking boom, environmental groups, such as Pacific Environment, Ratepayers for Affordable Clean Energy (RACE), and Rising Tide had moved to oppose them.

Some scientists and local residents have raised concerns about the potential effect of Poland's underground LNG storage infrastructure on marine life in the Baltic Sea.