Liquid-ring pump

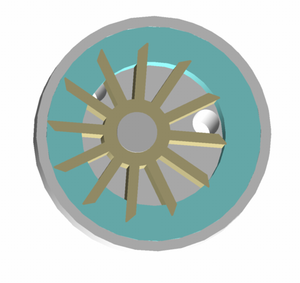

The liquid-ring pump compresses gas by rotating a vaned impeller located eccentrically within a cylindrical casing.

Liquid (often water) is fed into the pump, and by centrifugal acceleration forms a moving cylindrical ring against the inside of the casing.

This liquid ring creates a series of seals in the spaces between the impeller vanes, which form compression chambers.

The reduction in volume caused by the impeller rotation compresses the gas, which exits through the discharge port in the side of the casing.

The compressed gas at the discharge of pump contains a small amount of the working fluid, which is usually removed in a vapor–liquid separator.

Other applications include soil remediation, where contaminated ground water is drawn from wells by vacuum.

These contaminants become concentrated as the liquid continues to recirculate, and eventually could cause damage and reduced life of the pump.

Since oil has a very low vapor pressure, oil-sealed liquid-ring vacuum pumps are typically air-cooled.

The ability to use any liquid allows the liquid-ring vacuum pump to be ideally suited for solvent (vapor) recovery.

For example, if a process such as distillation or a vacuum dryer is generating toluene vapors, then it is possible to use liquid toluene as the sealant, provided the cooling water is cold enough to keep the vapor pressure of the sealant liquid low enough to pull the desired vacuum.