Lithium titanate

[6] In recent years, along with other lithium ceramics, metatitanate pebbles have been the subject of research efforts towards tritium breeding materials in nuclear fusion applications.

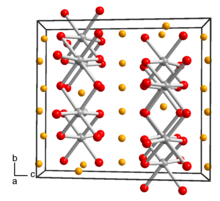

[8] A high-temperature cubic phase exhibiting solid-solution type behavior is referred to as γ-Li2TiO3 and is known to form reversibly above temperatures in the range 1150-1250 °C.

[9] A metastable cubic phase, isostructural with γ-Li2TiO3 is referred to as α-Li2TiO3; it is formed at low temperatures, and transforms to the more stable β-phase upon heating to 400 °C.

Li2TiO3 is used because it is capable of stabilizing the high capacity cathode conducting agents; LiMO2 (M=Fe, Mn, Cr, Ni).

This is advantageous because it does not create a solid electrolyte interface layer, which acts as a barrier to the ingress and egress of Li-ion to and from the anode.

[7] Li2TiO3 powder is most commonly prepared by the mixing of lithium carbonate, Ti-nitrate solution, and citric acid followed by calcination, compaction, and sintering.