Fractography

Fractography could show the allegation to be false, and that considerable force was needed to smash the bottle before using the broken end as a weapon to deliberately attack the victim.

Fractography can determine whether a cause of train derailment was a faulty rail, or if a wing of a plane had fatigue cracks before a crash.

Initial fractographic examination is commonly carried out on a macro scale utilising low power optical microscopy and oblique lighting techniques to identify the extent of cracking, possible modes and likely origins.

Optical microscopy or macrophotography are often enough to pinpoint the nature of the failure and the causes of crack initiation and growth if the loading pattern is known.

Common features that may cause crack initiation are inclusions, voids or empty holes in the material, contamination, and stress concentrations.

The SEM is especially useful when combined with Energy dispersive X-ray spectroscopy or EDX, which can be performed in the microscope, so very small areas of the sample can be analysed for their elemental composition.

The implant failed because of overload, all the imposed loads being concentrated at the connection between the catheter and the bag holding salt solution.

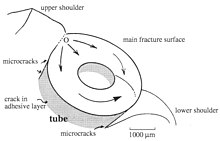

Further scanning electron microscopy showed numerous microcracks between the bag and the catheter, indicating that the adhesive bond between the two components had failed prematurely, perhaps through faulty manufacture.

The cyclic load and fatigue appeared to have progressively gone worse with some cracks being large and others being small in length and width indicating occasional force stronger than 2> g's.

[1] The study also found novel ways for Quantitative fractography to be used on aircraft, which compares load history (in this case the g-meter) and records of the alloy experiencing fatigue in a lab setting with different pressure, cycles, and temperatures.