Switch

[1][2] The most common type of switch is an electromechanical device consisting of one or more sets of movable electrical contacts connected to external circuits.

Switches in high-powered circuits must have special construction to prevent destructive arcing when they are opened.

The most familiar form of switch is a manually operated electromechanical device with one or more sets of electrical contacts, which are connected to external circuits.

The ideal switch is often used in circuit analysis as it greatly simplifies the system of equations to be solved, but this can lead to a less accurate solution.

Theoretical treatment of the effects of non-ideal properties is required in the design of large networks of switches, as for example used in telephone exchanges.

The contact material is chosen for its resistance to corrosion, because most metals form insulating oxides that would prevent the switch from working.

To prevent the formation of insulating oxides, a minimum wetting current may be specified for a given switch design.

When the contacts are separated by an insulating air gap, they are said to be "open", and no current can flow between them at normal voltages.

Their bouncing and non-synchronous closing of the switches is known as Hammond Click and compositions exist that use and emphasize this feature.

The plasma is of low resistance and is able to sustain power flow, even with the separation distance between the switch contacts steadily increasing.

[7] Where the voltage is sufficiently high, an arc can also form as the switch is closed and the contacts approach.

A puffer may be used to blow a sudden high velocity burst of gas across the switch contacts, which rapidly extends the length of the arc to extinguish it quickly.

In AC power service, the current periodically passes through zero; this effect makes it harder to sustain an arc on opening.

For this reason, power switches intended to interrupt a load current have spring mechanisms to make sure the transition between on and off is as short as possible regardless of the speed at which the user moves the rocker.

When a strongly inductive load such as an electric motor is switched off, the current cannot drop instantaneously to zero; a spark will jump across the opening contacts.

Providing a sufficient amount of wetting current is a crucial step in designing systems that use delicate switches with small contact pressure as sensor inputs.

Failing to do this might result in switches remaining electrically "open" due to contact oxidation.

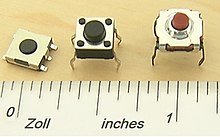

The moving part that applies the operating force to the contacts is called the actuator, and may be a toggle or dolly, a rocker, a push-button or any type of mechanical linkage (see photo).

The interior lamp of a household refrigerator is controlled by a switch that is held open when the door is closed.

One form of rotary switch consists of a spindle or "rotor" that has a contact arm or "spoke" which projects from its surface like a cam.

The word "toggle" is a reference to a kind of mechanism or joint consisting of two arms, which are almost in line with each other, connected with an elbow-like pivot.

In heating or cooling systems a sail switch ensures that air flow is adequate in a duct.

This type of switch performs much better than the ball tilt switch, as the liquid metal connection is unaffected by dirt, debris and oxidation, it wets the contacts ensuring a very low resistance bounce-free connection, and movement and vibration do not produce a poor contact.

Knife switches consist of a flat metal blade, hinged at one end, with an insulating handle for operation, and a fixed contact.

When the switch is closed, current flows through the hinged pivot and blade and through the fixed contact.

The knife and contacts are typically formed of copper, steel, or brass, depending on the application.

The disadvantages of the knife switch are the slow opening speed and the proximity of the operator to exposed live parts.

Metal-enclosed safety disconnect switches are used for isolation of circuits in industrial power distribution.

Sometimes spring-loaded auxiliary blades are fitted which momentarily carry the full current during opening, then quickly part to rapidly extinguish the arc.

When connected to a battery or other DC source, the 4-way switch selects from either normal or reversed polarity.