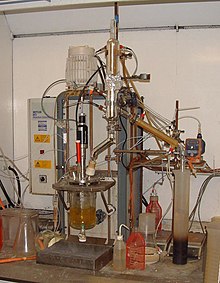

Reaction calorimeter

These factors are affected by the product composition, process temperature, agitation rate, viscosity, and liquid level.

Changes in product composition, liquid level, process temperature, agitation, or viscosity can impact the instrument's calibration.

It operates by controlling the jacket area of a laboratory reactor while maintaining a constant inlet temperature of the thermal fluid.

This method allows for precise temperature control, even during strongly exothermic or endothermic events, as additional cooling can be achieved by increasing the area over which heat is exchanged.

This system is generally more accurate than heat balance calorimetry, as changes in the delta temperature (Tout - Tin) are magnified by keeping the fluid flow as low as possible.

In the batch process, one reactant is added continuously in small amounts, to achieve complete conversion of the reaction.

This technology enables extended reaction processes, higher yield, conversion rate, selectivity, and automation.

By analyzing the heat flow data in conjunction with other analytical techniques, such as spectroscopy or chromatography, researchers can gain a comprehensive understanding of the reaction pathways and the factors influencing selectivity and yield.

This information is invaluable for developing efficient and sustainable chemical processes, reducing waste, and minimizing energy consumption.