Slip casting

[7] It seems to have been reinvented independently in England around 1745 "reputedly by Ralph Daniels of Corbridge",[8] and before long was widely used by European porcelain manufacturers, and then became the main forming technique for sanitaryware by the end of the century.

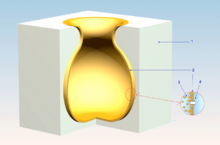

Due to capillary pressure from the mold, a semi-solid particulate layer is formed on the mould through deposition of the solids in the slip.

[24] To achieve an acceptable rate of cast formation and minimize drying shrinkage, a slip with a high content of solids is needed.

[25] Certain chemicals, known as deflocculants, are used to disperse agglomerates in the slip, and so decrease the viscosity and also allow a higher solids content; the latter is important to minimize drying shrinkage.

[26][27][28] Typical deflocculant additions used for a Vitreous China casting slip are 0.1-0.65%; the rheological properties of the clay components are the main influencing factors for the dosage.

[29] A mathematical formula developed by Alexandre Brongniart of Sèvres Porcelain is used to determine the dry material content of the slip.

The polymeric materials have much greater durability than plaster and, therefore, it is possible to achieve products with better dimensional tolerances and much longer mold life.

As far back as the Roman Empire, potters created what is termed "Barbotine ware" by using clay slip to decorate the surface of pots.