Surface acoustic wave

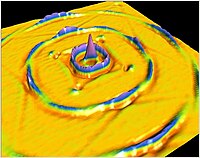

[2][3] SAWs were first explained in 1885 by Lord Rayleigh, who described the surface acoustic mode of propagation and predicted its properties in his classic paper.

[4] Named after their discoverer, Rayleigh waves have a longitudinal and a vertical shear component that can couple with any media like additional layers in contact with the surface.

This coupling strongly affects the amplitude and velocity of the wave, allowing SAW sensors to directly sense mass and mechanical properties.

Electronic devices employing SAWs normally use one or more interdigital transducers (IDTs) to convert acoustic waves to electrical signals and vice versa by exploiting the piezoelectric effect of certain materials, like quartz, lithium niobate, lithium tantalate, lanthanum gallium silicate, etc.

Complementing technology to SAW for frequencies above 1.5-2.5 GHz is based on thin-film bulk acoustic resonators (TFBAR, or FBAR).

[6] Sensor applications include all areas of sensing (such as chemical, optical, thermal, pressure, acceleration, torque and biological).

They are often used in applications such as garage door opener remote controls, short range radio frequency links for computer peripherals, and other devices where channelization is not required.

Where a radio link might use several channels, quartz crystal oscillators are more commonly used to drive a phase locked loop.

Since the resonant frequency of a SAW device is set by the mechanical properties of the crystal, it does not drift as much as a simple LC oscillator, where conditions such as capacitor performance and battery voltage will vary substantially with temperature and age.

This is helpful in applications where a single antenna must be shared between a transmitter and a receiver operating at closely spaced frequencies.

SAW filters are also frequently used in television receivers, for extracting subcarriers from the signal; until the analog switchoff, the extraction of digital audio subcarriers from the intermediate frequency strip of a television receiver or video recorder was one of the main markets for SAW filters.

Early pioneer Jeffery Collins incorporated surface acoustic wave devices in a Skynet receiver he developed in the 1970s.

As a result, QA offers a different perspective of the quantum regime in terms of wavelengths which QO has not covered.

Although this technique was first thought of as a way to accurately define a standard unit of current,[24] it turned out to be more useful in the field of quantum information.

By applying a voltage over the material, the charge carriers may obtain a higher drift speed than the SAW.

[28] In recent years, attention has been drawn to using SAWs to drive microfluidic actuation and a variety of other processes.

[9] It is this longitudinal wave that creates the flow of fluid within the microfluidic droplet, allowing mixing to take place.

If living organisms need to be kept alive, it is important to monitor and control their environment, such as heat and pH levels; however, if these elements are not regulated, the cells may die or it may result in unwanted reactions.

[42] The use of SAW as a way to heat these PDMS devices, along with liquids inside microchannels, is now a technique that can be done in a controlled manner with the ability to manipulate the temperature to within 0.1 °C.

[42][43] The development of Flexible Surface Acoustic Wave (SAW) devices has been a significant driver in the advancement of wearable technology and microfluidic systems.

These devices are typically fabricated on polymer substrates, such as Polyethylene Naphthalate (PEN) and polyimide, and utilize sputtering deposition of materials like AlN and ZnO.