Tie (cavity wall)

As time has passed, many galvanized steel ties have deteriorated due to moisture in the outer leaf of brickwork.

Any cracks appearing in cavity walls dating from the twentieth century need to be investigated before irremediable damage ensues.

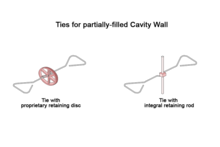

Due to the need for thicker insulation in exterior walls these days, a range of longer ties are now available so that cavities of up to 6"(150mm) can be constructed.

Ties in a cavity wall are typically made of iron, steel, or plastic; though figures are various.

It arises when the galvanizing is not of sufficient quality and the outer leaf of the cavity wall allows water penetration, usually due to porous brick/blockwork.

If the tie rusts, the swelling effect may cause horizontal, external cracks to appear in the wall.

Since ties in a cavity wall are typically made of metal (iron or steel), they are prone to corrode over time.

Cracks caused by vertical loads leave parts of buildings vulnerable to corrosion, such as eaves and gable walls above purlin positions, or placed directly beneath openings, where the weight on brickwork is light.

The major factors of the corrosion are: Cement-based mortar, giving an alkaline environment for cavity wall ties, has been used since the Second World War.

say that cavity wall insulation enhance the ability to grab water longer, so that the environment of the ties damper.

elevations warmed by the sunlight are warmer, letting ties more at risk for this type of corrosion.