Tunnel

It is dug through surrounding soil, earth or rock, or laid under water, and is usually completely enclosed except for the two portals common at each end, though there may be access and ventilation openings at various points along the length.

Utility tunnels are used for routing steam, chilled water, electrical power or telecommunication cables, as well as connecting buildings for convenient passage of people and equipment.

For example, in the United Kingdom, a road tunnel is defined as "a subsurface highway structure enclosed for a length of 150 metres (490 ft) or more.

"[7] The word "tunnel" comes from the Middle English tonnelle, meaning "a net", derived from Old French tonnel, a diminutive of tonne ("cask").

The modern meaning, referring to an underground passageway, evolved in the 16th century as a metaphor for a narrow, confined space like the inside of a cask.

In the Gaza Strip, the network of tunnels was used by Jewish strategists as rock-cut shelters, in first links to Judean resistance against Roman rule in the Bar Kokhba revolt during the 2nd century AD.

A major tunnel project must start with a comprehensive investigation of ground conditions by collecting samples from boreholes and by other geophysical techniques.

It is common practice to locate a tunnel deeper than otherwise would be required, in order to excavate through solid rock or other material that is easier to support during construction.

Conventional desk and preliminary site studies may yield insufficient information to assess such factors as the blocky nature of rocks, the exact location of fault zones, or the stand-up times of softer ground.

[25] Maintenance costs of a massive bridge to allow the world's largest ships to navigate under were considered higher than for a tunnel.

Political disputes can occur, as in 2005 when the US House of Representatives approved a $100 million federal grant to build a tunnel under New York Harbor.

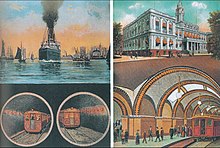

[30] This, and the availability of electric traction, brought about London Underground's switch to bored tunnels at a deeper level towards the end of the 19th century.

This method of cut and cover construction required relatively little disturbance of property during the renewal of the United Kingdom's then ancient sewerage systems.

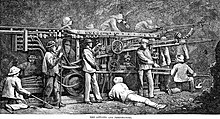

It was also used during the First World War by Royal Engineer tunnelling companies placing mines beneath German lines, because it was almost silent and so not susceptible to listening methods of detection.

In certain predominantly urban applications, tunnel boring is viewed as a quick and cost-effective alternative to laying surface rails and roads.

Some TBMs, the bentonite slurry and earth-pressure balance types, have pressurized compartments at the front end, allowing them to be used in difficult conditions below the water table.

Despite these difficulties, TBMs are now preferred over the older method of tunnelling in compressed air, with an airlock/decompression chamber some way back from the TBM, which required operators to work in high pressure and go through decompression procedures at the end of their shifts, much like deep-sea divers.

In February 2010, Aker Wirth delivered a TBM to Switzerland, for the expansion of the Linth–Limmern Power Stations located south of Linthal in the canton of Glarus.

As of August 2013[update], the world's largest TBM was "Big Bertha", a 17.5-metre (57.5 ft) diameter machine built by Hitachi Zosen Corporation, which dug the Alaskan Way Viaduct replacement tunnel in Seattle, Washington (US).

During construction of a tunnel it is often convenient to install a temporary railway, particularly to remove excavated spoil, often narrow gauge so that it can be double track to allow the operation of empty and loaded trains at the same time.

Construction began in July 2013 using "Bertha", at the time the world's largest earth pressure balance tunnel boring machine, with a 17.5-metre (57.5 ft) cutterhead diameter.

[50] The lower level, intended for commuter rail, saw passenger service after completion of the East Side Access project, in late 2022.

[51] In the UK, the 1934 Queensway Tunnel under the River Mersey between Liverpool and Birkenhead was originally to have road vehicles running on the upper deck and trams on the lower.

[57] These tunnels can be used for many types of utilities, routing steam, chilled water, electrical power or telecommunication cables, as well as connecting buildings for convenient passage of people and equipment.

Motor vehicle tunnels usually require ventilation shafts and powered fans to remove toxic exhaust gases during routine operation.

When two wavefronts of the same sign meet the train, significant and rapid air pressure[60] may cause ear discomfort[61] for passengers and crew.

[65] According to an article issued by Steve Hymon of TheSource – Transportation News and Views, there was no serious damage sustained by the LA subway system.

Excavation techniques, as well as the construction of underground bunkers and other habitable areas, are often associated with military use during armed conflict, or civilian responses to threat of attack.

Elaborately engineered 300-metre (1,000 ft) tunnels built to smuggle drugs across the Mexico-US border were estimated to require up to 9 months to complete, and an expenditure of up to $1 million.

[94] Some of these tunnels were equipped with lighting, ventilation, telephones, drainage pumps, hydraulic elevators, and in at least one instance, an electrified rail transport system.