Aerographite

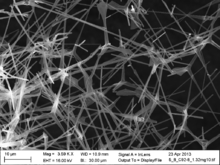

[1] Owing to its interconnected tubular network structure, aerographite resists tensile forces much better than other carbon foams as well as silica aerogels.

[1] The density given by the authors is based on a mass measurement and the determination of the outer volume of the synthetic foams as usually performed also for other structures.

Aerographite is superhydrophobic, thus its centimeter-sized samples repel water; they are also rather sensitive to electrostatic effects and spontaneously jump to charged objects.

Originally demonstrated on just μm-sized meshed graphite networks, the CVD mechanism had been adopted after 2014 by other scientists to create nm-sized carbon structures.

The template consists of micron-thick rods, often in the shape of multipods, that can be synthesized by mixing comparable amounts of Zn and polyvinyl butyral powders and heating the mixture at 900 °C.

A thin (~15 nm), discontinuous layer of carbon is deposited on ZnO which is then etched away by adding hydrogen gas to the reaction chamber.

[1] Aerographite electrodes have been tested in an electric double-layer capacitor (EDLC, also known as supercapacitor) and endured the mechanical shocks related to loading-unloading cycles and crystallization of the electrolyte (that occurs upon evaporation of the solvent).