Bakewell, Pears and Company

The original company name was Bakewell and Ensell, and the factory was called the Pittsburgh Flint Glass Manufactory.

Sarah Palmer became romantically involved with a young English clerk in Bakewell's firm named Thomas Pears, and they married in 1806.

[6] The import business thrived enough that by 1807, Bakewell owned multiple houses and stores in New York—plus land in Vermont, New Jersey and Pennsylvania.

Because of war between France and Great Britain, American ships' cargoes and crews were always under the threat of being confiscated by those two naval powers.

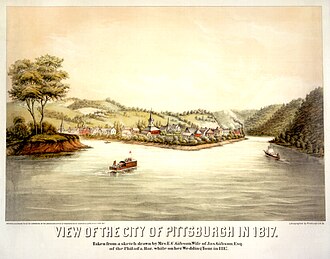

It was closer to the growing new western territories than the Atlantic Coast glass factories that were separated by the Allegheny Mountains.

[22] Much of the crystal available in the United States during the early 1800s was imported from England, and Bakewell employed English and French craftsmen to compete in that market.

Some of the raw materials used to make glass were delivered by wagon from Philadelphia and New Jersey—a considerable distance for the time that was difficult to travel because the Allegheny Mountains had to be crossed.

[34] Among the new hires in 1810 was former factory superintendent and glass cutter William Peter Eichbaum, who cut the first crystal chandelier made in America.

[36] Although many European countries forbade their glassworkers to come to the United States as part of an effort to retain glassmaking secrets, Bakewell improved his workforce by smuggling skilled glass workers from England to Pittsburgh.

The Embargo Act of 1807, and then the War of 1812, made it nearly impossible for American companies to acquire the raw materials necessary to produce good quality crystal.

[40] However, the lack of European goods also meant that consumers in the United States became dependent on domestic producers for manufactured products.

[42] In the case of Benjamin Bakewell and Company, domestic sources of red lead and good sand had been discovered.

[48] During that year, Thomas Bakewell visited England to recruit more skilled glassworkers and to acquire samples of English glassware.

[51] At that time, England began dumping low–priced glass products in the United States while keeping its price for red lead high.

[Note 8] A partnership called Page, Bakewell & Bostwick existed in 1814 and 1815 for the purpose of making black glass bottles.

[59] Pears went to England and France in 1816 and 1818 to recruit workers, and family members believe he used a disguise to evade authorities.

[65] When President James Monroe visited Pittsburgh in September 1817, Bakewell also presented him with a pair of elegant cut glass decanters.

[67] After the failure of the bottle works, Thomas Pears began selling Bakewell glass and collecting debt for the company.

[77] In March 1823 the company expanded its facility and added a new furnace as part of a plan to sell more lower-cost tableware.

[82] The flask was made of pressed glass decorated with a sheaf of rye on one side and a steamboat encircled with "The American System" on the other.

[86] American Revolutionary War hero Marquis de Lafayette began touring the United States in 1824, and he arrived in Pittsburgh in 1825.

[84] John Palmer Bakewell, son of Benjamin, applied for a patent on September 9, 1825, for an "improvement in making glass furniture knobs".

[97] One author called mechanical pressing "the greatest contribution of America to glassmaking, and the most important development since the Romans discovered glassblowing".

[101] In addition to its leadership in cut and engraved glassware, the company became a leading manufacturer of plain and molded tableware—including colored glass and pressed ware.

[102][Note 13] The United States economy was not good during the late 1830s, and this caused Bakewells and Company to shut down its furnaces for four months during 1838.

While the old version of the company was a leader in cut and engraved crystal glassware, luxury goods were now only a small niche of the portfolio of glass products.

Jacob W. Paul, brother-in-law of John Palmer Pears, became a partner in 1864—while Benjamin Page Bakewell retired in August.

Between 1868 and 1874, partners in the company also received patents related to pressing, molds, and encased (double or cased) glass.

[121] During this time, glass factories were trying to survive in an economic depression, and the three men deemed most responsible for the success of Bakewell were all dead.

[127] The 1880 United States census listed Pittsburgh's Allegheny County as the largest glass producer in the nation based on value, and its market share was 26.8 percent.

Metropolitan Museum of Art

Metropolitan Museum of Art

Metropolitan Museum of Art

Metropolitan Museum of Art