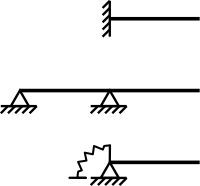

Cantilever

In an architectural application, Frank Lloyd Wright's Fallingwater used cantilevers to project large balconies.

The roof built over the stands at Old Trafford uses a cantilever so that no supports will block views of the field.

The largest cantilevered roof in Europe is located at St James' Park in Newcastle-Upon-Tyne, the home stadium of Newcastle United F.C.

A single-spar design will usually be fitted with a second smaller drag-spar nearer the trailing edge, braced to the main spar via additional internal members or a stressed skin.

The wing must also resist twisting forces, achieved by cross-bracing or otherwise stiffening the main structure.

Cantilever wings require much stronger and heavier spars than would otherwise be needed in a wire-braced design.

[5] Other changes such as enclosed cockpits, retractable undercarriage, landing flaps and stressed-skin construction furthered the design revolution, with the pivotal moment widely acknowledged to be the MacRobertson England-Australia air race of 1934, which was won by a de Havilland DH.88 Comet.

[6] Currently, cantilever wings are almost universal with bracing only being used for some slower aircraft where a lighter weight is prioritized over speed, such as in the ultralight class.

The fabrication process typically involves undercutting the cantilever structure to release it, often with an anisotropic wet or dry etching technique.

A large number of research groups are attempting to develop cantilever arrays as biosensors for medical diagnostic applications.

The first is Stoney's formula, which relates cantilever end deflection δ to applied stress σ: where

Very sensitive optical and capacitive methods have been developed to measure changes in the static deflection of cantilever beams used in dc-coupled sensors.

The frequency shift can be measured with exquisite accuracy using heterodyne techniques and is the basis of ac-coupled cantilever sensors.

The principal advantage of MEMS cantilevers is their cheapness and ease of fabrication in large arrays.

The challenge for their practical application lies in the square and cubic dependences of cantilever performance specifications on dimensions.

These superlinear dependences mean that cantilevers are quite sensitive to variation in process parameters, particularly the thickness as this is generally difficult to accurately measure.

A chemical sensor can be obtained by coating a recognition receptor layer over the upper side of a microcantilever beam.

[12] A typical application is the immunosensor based on an antibody layer that interacts selectively with a particular immunogen and reports about its content in a specimen.

In the static mode of operation, the sensor response is represented by the beam bending with respect to a reference microcantilever.

[13] Surface stress on microcantilever, due to receptor-target binding, which produces cantilever deflection can be analyzed using optical methods like laser interferometry.