Electric generator

The principle, later called Faraday's law, is that an electromotive force is generated in an electrical conductor which encircles a varying magnetic flux.

This design was inefficient, due to self-cancelling counterflows of current in regions of the disk that were not under the influence of the magnetic field.

This counterflow limited the power output to the pickup wires and induced waste heating of the copper disc.

Later homopolar generators would solve this problem by using an array of magnets arranged around the disc perimeter to maintain a steady field effect in one current-flow direction.

In the first practical electric generators, called dynamos, the AC was converted into DC with a commutator, a set of rotating switch contacts on the armature shaft.

The commutator reversed the connection of the armature winding to the circuit every 180° rotation of the shaft, creating a pulsing DC current.

[5][6][7] The modern dynamo, fit for use in industrial applications, was invented independently by Sir Charles Wheatstone, Werner von Siemens and Samuel Alfred Varley.

Varley took out a patent on 24 December 1866, while Siemens and Wheatstone both announced their discoveries on 17 January 1867 by delivering papers at the Royal Society.

His machine was a "rotating rectangle", whose operation was heteropolar: each active conductor passed successively through regions where the magnetic field was in opposite directions.

Ferranti went on to design the Deptford Power Station for the London Electric Supply Corporation in 1887 using an alternating current system.

This "bootstrap" process continues until the magnetic field in the core levels off due to saturation and the generator reaches a steady state power output.

A potential difference is created between the center of the disc and the rim (or ends of the cylinder), the electrical polarity depending on the direction of rotation and the orientation of the field.

[18] They are unusual in that they can produce tremendous electric current, some more than a million amperes, because the homopolar generator can be made to have very low internal resistance.

A magnetohydrodynamic generator directly extracts electric power from moving hot gases through a magnetic field, without the use of rotating electromagnetic machinery.

Induction generators operate by mechanically turning their rotor faster than the simultaneous speed, giving negative slip.

Induction generators are useful in applications like minihydro power plants, wind turbines, or in reducing high-pressure gas streams to lower pressure, because they can recover energy with relatively simple controls.

In the simplest form of linear electric generator, a sliding magnet moves back and forth through a solenoid, a copper wire or a coil.

Mechanical speed-regulating devices may waste a significant fraction of the input energy to maintain a required fixed frequency.

Where it is impractical or undesired to tightly regulate the speed of the prime mover, doubly fed electric machines may be used as generators.

With the assistance of power electronic devices, these can regulate the output frequency to a desired value over a wider range of generator shaft speeds.

Allowing a wider range of prime mover speeds can improve the overall energy production of an installation, at the cost of more complex generators and controls.

Most power stations in the world burn fossil fuels such as coal, oil, and natural gas to generate electricity.

Cleaner sources include nuclear power, and increasingly use renewables such as the sun, wind, waves and running water.

Motor vehicles require electrical energy to power their instrumentation, keep the engine itself operating, and recharge their batteries.

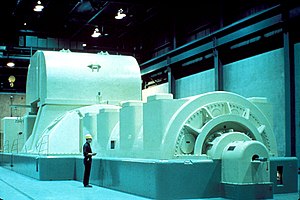

An engine-generator is the combination of an electrical generator and an engine (prime mover) mounted together to form a single piece of self-contained equipment.

Many different versions of engine-generators are available – ranging from very small portable petrol powered sets to large turbine installations.

The primary advantage of engine-generators is the ability to independently supply electricity, allowing the units to serve as backup power sources.

[21] A generator can also be driven by human muscle power (for instance, in field radio station equipment).

Typically operated by means of pedal power, a converted bicycle trainer, or a foot pump, such generators can be practically used to charge batteries, and in some cases are designed with an integral inverter.

In particular, inductance can be added to allow for the machine's windings and magnetic leakage flux,[24] but a full representation can become much more complex than this.

- G, generator

- V G , generator open-circuit voltage

- R G , generator internal resistance

- V L , generator on-load voltage

- R L , load resistance