EEPROM

It is used in computers, usually integrated in microcontrollers such as smart cards and remote keyless systems, or as a separate chip device, to store relatively small amounts of data by allowing individual bytes to be erased and reprogrammed.

[1][2] In the early 1970s, some studies, inventions, and development for electrically re-programmable non-volatile memories were performed by various companies and organizations.

In general, programmable memories, including EPROM, of early 1970s had reliability and endurance problems such as the data retention periods and the number of erase/write cycles.

Intel,[17][18] NEC (later, Renesas Electronics),[19] Philips (later, NXP Semiconductors),[20] Siemens (later, Infineon Technologies),[21] Honeywell (later, Atmel),[22] Texas Instruments,[23] studied, invented, and manufactured some electrically re-programmable non-volatile devices until 1977.

[24] In February 1977, Israeli-American Eliyahou Harari at Hughes Aircraft Company patented in the US a modern EEPROM technology, based on Fowler-Nordheim tunnelling through a thin silicon dioxide layer between the floating-gate and the wafer.

[32] But this device required additional 20–22V VPP bias voltage supply for byte erase, except for 5V read operations.

[33]: 5–86 In 1981, Perlegos and 2 other members left Intel to form Seeq Technology,[34] which used on-device charge pumps to supply the high voltages necessary for programming E2PROMs.

[35][36] Electrically alterable read-only memory (EAROM) is a type of EEPROM that can be modified one or a few bits at a time.

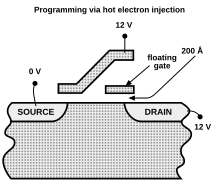

As is described in former section, old EEPROMs are based on avalanche breakdown-based hot-carrier injection with high reverse breakdown voltage.

But FLOTOX theoretical basis is Fowler–Nordheim tunneling hot-carrier injection through a thin silicon dioxide layer between the floating gate and the wafer.

But each FLOTOX structure is in conjunction with another read-control transistor because the floating gate itself is just programming and erasing one data bit.

[39] Intel's FLOTOX device structure improved EEPROM reliability, in other words, the endurance of the write and erase cycles, and the data retention period.

After sufficient number of rewrite cycles, the difference becomes too small to be recognizable, the cell is stuck in programmed state, and endurance failure occurs.

[46] During storage, the electrons injected into the floating gate may drift through the insulator, especially at increased temperature, and cause charge loss, reverting the cell into erased state.

EEPROM can be programmed and erased electrically using field electron emission (more commonly known in the industry as "Fowler–Nordheim tunneling").

EPROMs can't be erased electrically and are programmed by hot-carrier injection onto the floating gate.