Forensic materials engineering

Metal surfaces can be analyzed in a number of ways, including by spectroscopy and EDX used during scanning electron microscopy.

Hard products like ceramic pottery and glass windscreens can be studied using the same SEM methods used for metals, especially ESEM conducted at low vacuum.

The slicing method is preferable since there are no complications from solvent absorption, and the integrity of the sample is partly preserved.

Although polymers usually possess quite different properties to metals and ceramics, they are just as susceptible to failure from mechanical overload, fatigue and stress corrosion cracking if products are poorly designed or manufactured.

Many plastics are susceptible to attack by active chemicals like chlorine, present at low levels in potable water supplies, especially if the injection mouldings are faulty.

Specimens will be exposed to a vacuum, so any volatiles may be removed, and surfaces may be contaminated by substances used to attach the sample to the mount.

Attenuated total reflectance infra-red spectroscopy is useful because the product is usually flexible so can be pressed against the selenium crystal used for analysis.

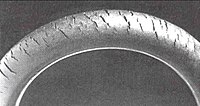

The problem occurs when small concentrations of ozone gas are present near to exposed elastomer surfaces, such as O-rings and diaphragm seals.