Forensic polymer engineering

Although polymers usually possess quite different properties to metals, ceramics and glasses, they are just as susceptible to failure from mechanical overload, fatigue and stress corrosion cracking if products are poorly designed or manufactured.

Scanning electron microscopy or ESEM is especially useful for examining fracture surfaces and can also provide elemental analysis of viewed parts of the sample being investigated.

Specimens will be exposed to a partial vacuum, so any volatiles may be removed, and surfaces may be contaminated by substances used to attach the sample to the mount.

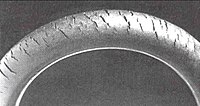

Many polymers are attacked by specific chemicals in the environment, and serious problems can arise, including road accidents and personal injury.

They are all highly susceptible to ozone attack, and can cause problems like vehicle fires (from rubber fuel lines) and tyre blow-outs.

Another highly reactive gas is chlorine, which will attack susceptible polymers such as acetal resin and polybutylene pipework.

The discoloration on the fracture surface was caused by deposition of carbonates from the hard water supply, so the joint had been in a critical state for many months.

Scanning electron microscopy or SEM showed that the nylon connector had fractured by stress corrosion cracking due to a small leak of battery acid.

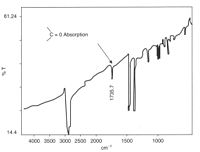

Polyesters are prone to degrade when treated with strong acids, and in all these cases, care must be taken to dry the raw materials for processing at high temperatures to prevent the problem occurring.

The point of attack occurs at the tertiary carbon atom present in every repeat unit, causing oxidation and finally chain breakage.

The branch points are tertiary carbon atoms, so polymer degradation starts there and results in chain cleavage, and embrittlement.