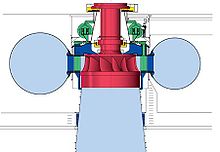

Francis turbine

The power output of the electric generators generally ranges from just a few kilowatts up to 1000 MW, though mini-hydro installations may be lower.

In 1826 the French engineer Benoit Fourneyron developed a high-efficiency (80%) outward-flow water turbine.

In 1848 James B. Francis, while working as head engineer of the Locks and Canals company in the water wheel-powered textile factory city of Lowell, Massachusetts,[4] improved on these designs to create more efficient turbines.

He applied scientific principles and testing methods to produce a very efficient turbine design.

More importantly, his mathematical and graphical calculation methods improved turbine design and engineering.

Throughout its length, it has numerous openings at regular intervals to allow the working fluid to impinge on the blades of the runner.

This maintains a constant velocity despite the fact that numerous openings have been provided for the fluid to enter the blades, as the cross-sectional area of this casing decreases uniformly along the circumference.

These are the centers where the fluid strikes and the tangential force of the impact produces torque causing the shaft of the turbine to rotate.

Close attention to design of blade angles at inlet and outlet is necessary, as these are major parameters affecting power production.

Its primary function is to reduce the velocity of discharged water to minimize the loss of kinetic energy at the outlet.

[5] This means that it is a ratio indicating the fraction of total change in fluid pressure energy occurring in the blades of the turbine.

The rest of the changes occur in the stator blades of the turbines and the volute casing as it has a varying cross-sectional area.

Francis type units cover a head range from 40 to 600 m (130 to 2,000 ft), and their connected generator output power varies from just a few kilowatts up to 1000 MW.

The turbine and the outlet channel may be placed lower than the lake or sea level outside, reducing the tendency for cavitation.

In addition to electrical production, they may also be used for pumped storage, where a reservoir is filled by the turbine (acting as a pump) driven by the generator acting as a large electrical motor during periods of low power demand, and then reversed and used to generate power during peak demand.