Fusion bonded epoxy coating

It is also commonly used to protect reinforcing bars (though being phased out as of 2005[1]) and on a wide variety of piping connections, valves etc.

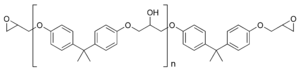

The name fusion-bond epoxy is due to resigning cross-link and the application method, which is different from a conventional paint.

[4] The resin and hardener components in the dry powder FBE stock remain unreacted at normal storage conditions.

At typical coating application temperatures, usually in the range of 180 to 250 °C (356 to 482 °F), the contents of the powder melt and transform to a liquid form.

The liquid FBE film wets and flows onto the steel surface on which it is applied, and soon becomes a solid coating by chemical cross-linking, assisted by heat.

Various types of curing agents, used in FBE manufacture, include dicyandiamide, aromatic amines, aliphatic diamines and organic acid anhydrides.

[6] The selected curing agent determines the nature of the final FBE product – its cross linking density, chemical resistance, brittleness, flexibility etc.

The ratio of epoxy resins and curing agents in a formulation is determined by their relative equivalent weights.

These components control characteristics such as permeability, hardness, colour, thickness, gouge resistance etc.

All of these components are normally dry solids, even though small quantities of liquid additives may be used in some FBE formulations.

Essential parts of a powder coating manufacturing plant are: The components of the FBE formulation are weighed and pre-blended in high speed mixers.

FBE extruders incorporate a single or dual screw setup, rotating within a fixed clamshell barrel.

Because of the fast operation of the extruder and relatively low temperature within the barrel, the epoxy and hardener components will not undergo a significant chemical reaction.

Another method of application is "fluid-dip" process, in which the heated components are dipped in a fluidized powder bed (see below).

The roughness of the steel achieved after blasting is referred to as profile, which is measured in micrometers or mils.

When used as a primer in a multi-layer polyolifine system, application temperature may be dropped based on FBE manufacturer's recommendations, in order to meet the "inter-coat adhesion" parameters.

An electrostatic spray gun incorporates an ionizer electrode on it, which gives the powder particles a positive electric charge.

The charged powder particles uniformly wraps around the substrate, and melts into a liquid form.