Nanodiamond

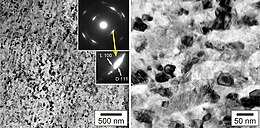

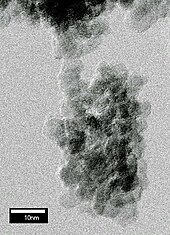

Detonation is often performed in a sealed, oxygen-free, stainless steel chamber and yields a mixture of nanodiamonds averaging 5 nm and other graphitic compounds.

[10] Because detonation synthesis results in a mix of nanodiamond particles and other graphitic carbon forms, extensive cleaning methods must be employed to rid the mixture of impurities.

In general, gaseous ozone treatment or solution-phase nitric acid oxidation is utilized to remove sp2 carbons and metal impurities.

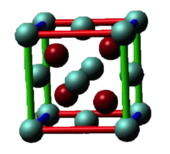

[12] In addition, high-yield synthesis of fluorescent nanodiamonds can be achieved by grinding electron-irradiated cubic crystalline diamond obtained from nitrogen-containing or nitrogen-free carbon precursors.

[17] Nanodiamonds share the hardness and chemical stability of visible-scale diamonds, making them candidates for applications such as polishes and engine oil additives for improved lubrication.

[3] Diamond nanoparticles have the potential to be used in myriad biological applications and due to their unique properties such as inertness and hardness, nanodiamonds may prove to be a better alternative to the traditional nanomaterials currently utilized to carry drugs, coat implantable materials, and synthesize biosensors and biomedical robots.

[23] Studies have shown that small photoluminescent diamond nanoparticles that remain free in the cytosol are excellent contenders for the transport of biomolecules.

[24] Nanodiamonds containing nitrogen-vacancy defects have been used as an ultrasensitive label for in vitro diagnostics, using a microwave field to modulate emission intensity and frequency-domain analysis to separate the signal from background autofluorescence.

[25] Combined with recombinase polymerase amplification, nanodiamonds enable single-copy detection of HIV-1 RNA on a low-cost lateral flow test format.

[21] In addition, the ability to surface functionalize nanodiamonds of small diameters provides various possibilities for diamond nanoparticles to be utilized as biolabels with potentially low cytotoxicity.

[21] Decreasing particle size and functionalizing their surfaces[21] may allow such surface-modified diamond nanoparticles to deliver proteins, which can then provide an alternative to traditional catalysts.

Boron-doped diamond (BDD) produced by energy-assisted (plasma or hot filament, HF) Chemical Vapor Deposition (CVD) processes is a good candidatein Dopamine detection, however it is not selective towards some interferents.

This issue, can be overcome via further post-synthesis treatments for BDD surface modifications including anodization, hydrogen plasma, etching into porous forms, carbon-based nanomaterials, polymer films and nanoparticles.

Recent studies,[28] propose a new approach for the realization of Titanium doped diamond-based electrodes with a native selectivity towards dopamine, through substrate pre-treatments (lapping, electropolishing and chemical etching) instead of post-process treatments.

[29] Those modifications, which can be summarised as an increase in the ionic conductivity of the system, thus of a decrease in the impedance, are likely due to the presence of functional groups on the nanodiamond particle surface.