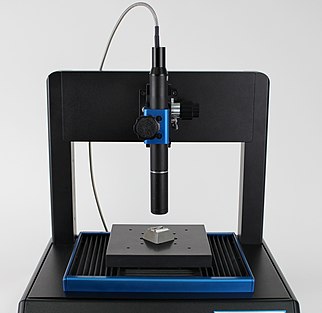

Profilometer

Non-scanning technologies measure the surface topography within a single camera acquisition, XYZ scanning is no longer needed.

A profilometer can measure small surface variations in vertical stylus displacement as a function of position.

The radius of diamond stylus ranges from 20 nanometres to 50 μm, and the horizontal resolution is controlled by the scan speed and data signal sampling rate.

Advantages of contact profilometers include acceptance, surface independence, resolution, it is a direct technique with no modeling required.

Time-resolved profilometers can be combined with a stroboscopic unit to measure MEMS vibrations in the MHz range.

The additional advantages of using fiber-based optical profilometers are flexibility, long profile acquisition, ruggedness, and ease of incorporating into industrial processes.

With the small diameter of certain probes, surfaces can be scanned even inside hard-to-reach spaces, such as narrow crevices or small-diameter tubes.

[5] Because these probes generally acquire one point at a time and at high sample speeds, acquisition of long (continuous) surface profiles is possible.

[6] Fiber-based probes are easily installed in-process, such as above moving webs or mounted onto a variety of positioning systems.