Suspension polymerization

Note 2: Monomer or monomer-solvent droplets in suspension polymerization havediameters usually exceeding 10 μm.

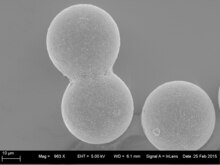

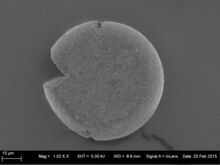

[4] Suspension polymerization is divided into two main types, depending on the morphology of the particles that result.

In powder polymerization, the polymer is not soluble in its monomer and the resultant bead will be porous and irregular.

The size is controlled by the stirring speed, the volume fraction of monomer, the concentration and identity of the stabilizers used, and the viscosities of the different components.

The following equation derived empirically summarizes some of these interactions: d is the average particle size, k includes parameters related to the reaction vessel design, Dv is the reaction vessel diameter, Ds is the diameter of the stirrer, R is the volume ratio of the monomer to the liquid matrix, N is the stirring speed, νm and νl are the viscosity of the monomer phase and liquid matrix respectively, ε is the interfacial tension of the two phases, and Cs is the concentration of stabilizer.