Tantalum nitride

As a thin film TaN find use as a diffusion barrier and insulating layer between copper interconnects in the back end of line of computer chips.

Methods of depositing the films include RF-magnetron-reactive sputtering,[3][4] Direct current (DC) sputtering,[5] Self-propagating high-temperature synthesis (SHS) via 'combustion' of tantalum powder in nitrogen,[1] low‐pressure metalorganic chemical vapor deposition (LP‐MOCVD),[6] ion beam assisted deposition (IBAD),[7] and by electron beam evaporation of tantalum in concert with high energy nitrogen ions.

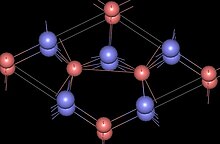

[8] Depending on the relative amount of N2, the deposited film can vary from (fcc) TaN to (hexagonal) Ta2N as nitrogen decreases.

[9] It is sometimes used in integrated circuit manufacture to create a diffusion barrier or "glue" layers between copper, or other conductive metals.

[3] It has the advantage over nichrome resistors of forming a passivating oxide film which is resistant to moisture.