Torrefaction

To create efficient biomass-to-energy chains, torrefaction of biomass, combined with densification (pelletisation or briquetting), is a promising step towards overcoming the logistical challenges in developing large-scale sustainable energy solutions, by making it easier to transport and store.

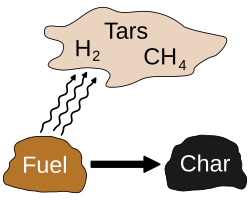

During the process, the biomass typically loses 20% of its mass (bone dry basis) and 10% of its heating value, with no appreciable change in volume.

After the biomass is torrefied it can be densified, usually into briquettes or pellets using conventional densification equipment, to increase its mass and energy density and to improve its hydrophobic properties.

The final product may repel water and thus can be stored in moist air or rain without appreciable change in moisture content or heating value, unlike the original biomass.

Torrefied biomass has hydrophobic properties, i.e., repels water, and when combined with densification make bulk storage in open air feasible.

[7] This leads to more efficient co-firing in existing coal-fired power stations or entrained-flow gasification for the production of chemicals and transportation fuels.

Wood powder fuel: Large-scale co-firing in coal-fired power plants: Steel production: Residential/decentralized heating: Biomass-to-Liquids: Miscellaneous uses: