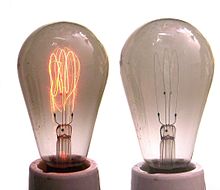

Incandescent light bulb

Historians Robert Friedel and Paul Israel list inventors of incandescent lamps prior to Joseph Swan and Thomas Edison of General Electric.

[9] Limelight became a popular form of stage lighting in the early 19th century, by heating a piece of calcium oxide to incandescence with an oxyhydrogen torch.

[10] In 1802, Humphry Davy used what he described as "a battery of immense size",[11] consisting of 2,000 cells housed in the basement of the Royal Institution of Great Britain,[12] to create an incandescent light by passing the current through a thin strip of platinum, chosen because the metal had an extremely high melting point.

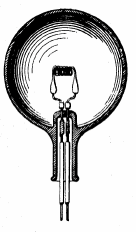

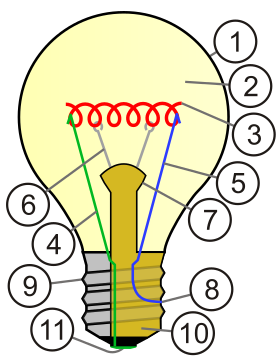

[17] In 1840, British scientist Warren De la Rue enclosed a coiled platinum filament in a vacuum tube and passed an electric current through it.

In 1841, Frederick de Moleyns of England was granted the first patent for an incandescent lamp, with a design using platinum wires contained within a vacuum bulb.

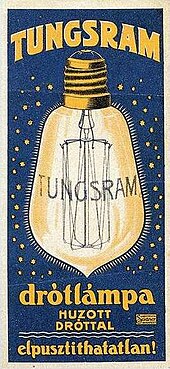

[25] Later he lived in the US, changed his name to Alexander de Lodyguine and applied for and obtained patents for incandescent lamps having chromium, iridium, rhodium, ruthenium, osmium, molybdenum and tungsten filaments.

[26] On 24 July 1874, a Canadian patent was filed by Henry Woodward and Mathew Evans for a lamp consisting of carbon rods mounted in a nitrogen-filled glass cylinder.

Judges of four courts raised doubts about the alleged Göbel anticipation, but there was never a decision in a final hearing due to the expiration of Edison's patent.

By 1860, he was able to demonstrate a working device but the lack of a good vacuum and an adequate supply of electricity resulted in a short lifetime for the bulb and an inefficient source of light.

[33] With the help of Charles Stearn, an expert on vacuum pumps, in 1878, Swan developed a method of processing that avoided the early bulb blackening.

Edison continued to improve this design and by 4 November 1879, filed for a US patent for an electric lamp using "a carbon filament or strip coiled and connected ... to platina contact wires.

Eventually on 6 October 1889, a judge ruled that Edison's electric light improvement claim for "a filament of carbon of high resistance" was valid.

[58] However, about 1893, Italian inventor Arturo Malignani [it] (1865–1939), who lacked these pumps, discovered that phosphorus vapours did the job of chemically binding the remaining amounts of water and oxygen.

Lodygin invented a process where rare metals such as tungsten can be chemically treated and heat-vaporized onto an electrically heated thread-like wire (platinum, carbon, gold) acting as a temporary base or skeletal form.

[67] In 1913, Irving Langmuir found that filling a lamp with inert gas (nitrogen at first, and later argon) instead of a vacuum resulted in twice the luminous efficacy and reduced bulb blackening.

[71] Between 1924 and the outbreak of the Second World War, the Phoebus cartel attempted to fix prices and sales quotas for bulb manufacturers outside of North America.

Production of krypton filled lamps based on his invention started at Ajka in 1937, in a factory co-designed by Polányi and Hungarian-born physicist Egon Orowan.

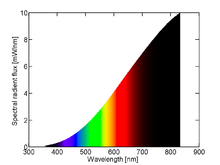

By careful selection of fluorescent phosphor coatings or filters which modify the spectral distribution, the spectrum emitted can be tuned to mimic the appearance of incandescent sources, or other different color temperatures of white light.

Measures to ban light bulbs have been implemented in the European Union, the United States, Russia, Brazil, Argentina, Canada and Australia, among others.

[96][97] US Department of Energy research at Sandia National Laboratories initially indicated the potential for dramatically improved efficiency from a photonic lattice filament.

[99][100] More advanced reflectors based on interference filters or photonic crystals can theoretically result in higher efficiency, up to a limit of about 270 lm/W (40% of the maximum efficacy possible).

However, carbon filaments operate at lower temperatures than tungsten ones, so the effect of the fill gas was not significant as the heat losses offset any benefits.

The inventor, William Woods, along with his colleague at Corning Glass Works, David E. Gray, had created a machine that by 1939 was turning out 1,000 bulbs per minute.

The 2016 closing of Osram-Sylvania's Wellsboro, Pennsylvania plant meant that one of the last remaining ribbon machines in the United States was shut down.

These filaments have a positive temperature coefficient, like a metallic conductor, which stabilized the lamps operating properties against minor variations in supply voltage.

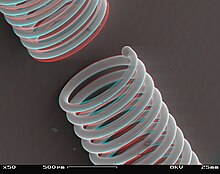

[113] During operation, the tungsten wire is stressed under the load of its own weight and because of the diffusion that can occur at high temperatures, grains begin to rotate and slide.

[122] Study of the problem of bulb blackening led to the discovery of thermionic emission, the invention of the vacuum tube, and evaporation deposition used to make mirrors and other optical coatings.

[126] Some old, high-powered lamps used in theater, projection, searchlight, and lighthouse service with heavy, sturdy filaments contained loose tungsten powder within the envelope.

Electrical contacts may carry a "T" rating symbol indicating that they are designed to control circuits with the high inrush current characteristic of tungsten lamps.

Very low voltages are inefficient since the lead wires would conduct too much heat away from the filament, so the practical lower limit for incandescent lamps is 1.5 volts.

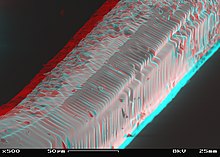

3D red cyan

glasses are recommended to view this image correctly.

3D red cyan

glasses are recommended to view this image correctly.

3D red cyan

glasses are recommended to view this image correctly.

3D red cyan

glasses are recommended to view this image correctly.