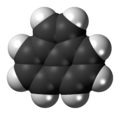

Acenaphthylene

It is produced industrially by gas phase dehydrogenation of acenaphthene.

[5] Polymerisation of acenaphthylene with acetylene in the presence of a Lewis acid catalyst gives electrically conductive polymers.

Acenaphthylene possesses excellent properties as an antioxidant in cross-linked polyethylene and ethylene-propylene rubber.

Thermal trimerization of acenaphthylene leads to decacyclene, which can be further processed to sulfur dyes.

[6] The no-observed-adverse-effect-level of acenaphthylene after repeated 28-day oral administration to both male and female rats was found to be 4 mg/kg/day.