Optical proximity correction

Optical proximity correction (OPC) is a photolithography enhancement technique commonly used to compensate for image errors due to diffraction or process effects.

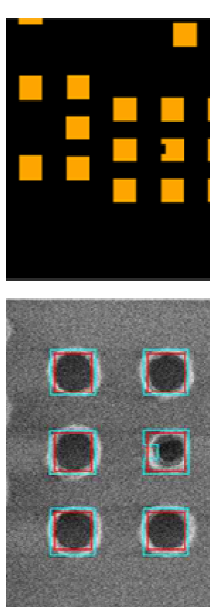

The need for OPC is seen mainly in the making of semiconductor devices and is due to the limitations of light to maintain the edge placement integrity of the original design, after processing, into the etched image on the silicon wafer.

Other distortions such as rounded corners are driven by the resolution of the optical imaging tool and are harder to compensate for.

This may be driven by pre-computed look-up tables based on width and spacing between features (known as rule based OPC) or by using compact models to dynamically simulate the final pattern and thereby drive the movement of edges, typically broken into sections, to find the best solution, (this is known as model based OPC).

The objective is to reproduce the original layout drawn by the designer on the semiconductor wafer as well as possible.

The two most visible benefits of OPC are correcting linewidth differences seen between features in regions of different density (e.g., center vs. edge of an array, or nested vs. isolated lines), and line end shortening (e.g., gate overlap on field oxide).

For the latter case, "dog-ear" (serif or hammerhead) features may be generated at the line end in the design.

It is often common to compare the critical feature width to this value, by defining a parameter,

As the feature pitch decreases, more components are truncated by the numerical aperture, resulting in greater difficulty to affect the pattern in the desired fashion.

The degree of coherence of the illumination source is determined by the ratio of its angular extent to the numerical aperture.

[2] Two image points separated by more than this distance will effectively be uncorrelated, allowing a simpler OPC application.

Aberrations in optical projection systems deform wavefronts, or the spectrum or spread of illumination angles, which can affect the depth of focus.

This approach will affect the application of OPC, as one will need to take into account the sum of the image intensities from each exposure.

In contrast to multiple exposure of the same photoresist film, multiple layer patterning entails repeated photoresist coating, deposition, and etching to pattern the same device layer.

Depending on the lithography tool used to image at these looser design rules, the OPC will be different.

Today, OPC is rarely practiced without the use of commercial packages from electronic design automation (EDA) vendors.

Advances in algorithms, modeling techniques and the use of large compute farms has enabled the most critical patterning layers to be corrected overnight, starting from the 130 nm design rules (when model based OPC was first used) [7] down to the most advanced design rules.

features which are commonly encountered today, but can be applied to any desired image correction scheme which can be modeled accurately.

[8] SRAFs have more pronounced effects on the diffraction spectrum than targeted feature resizing and/or attachments.

Generally, though, SRAFs cannot be a complete solution, and can only approach the dense case, not match it.