Probabilistic design

It deals primarily with the consideration and minimization of the effects of random variability upon the performance of an engineering system during the design phase.

Typically, these effects studied and optimized are related to quality and reliability.

It differs from the classical approach to design by assuming a small probability of failure instead of using the safety factor.

[2][3] Probabilistic design is used in a variety of different applications to assess the likelihood of failure.

From this perspective, probabilistic design predicts the flow of variability (or distributions) through a system.

[4] Because there are so many sources of random and systemic variability when designing materials and structures, it is greatly beneficial for the designer to model the factors studied as random variables.

By considering this model, a designer can make adjustments to reduce the flow of random variability, thereby improving engineering quality.

Proponents of the probabilistic design approach contend that many quality problems can be predicted and rectified during the early design stages and at a much reduced cost.

Minimizing random variability is essential to probabilistic design because it limits uncontrollable factors, while also providing a much more precise determination of failure probability.

Alternatively, it could be the only design option available, but with the optimum combination of input variables and parameters.

[4] Though the laws of physics dictate the relationships between variables and measurable quantities such as force, stress, strain, and deflection, there are still three primary sources of variability when considering these relationships.

[6] The first source of variability is statistical, due to the limitations of having a finite sample size to estimate parameters such as yield stress, Young's modulus, and true strain.

[7] Measurement uncertainty is the most easily minimized out of these three sources, as variance is proportional to the inverse of the sample size.

We can represent variance due to measurement uncertainties as a corrective factor

[6] The second source of variability stems from the inaccuracies and uncertainties of the model used to calculate such parameters.

These include the physical models we use to understand loading and their associated effects in materials.

and the model error takes the general form:

There is a fundamental random uncertainty associated with all physical phenomena, and it is comparatively the most difficult to minimize this variability.

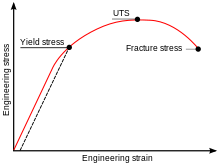

Consider the classical approach to performing tensile testing in materials.

The stress experienced by a material is given as a singular value (i.e., force applied divided by the cross-sectional area perpendicular to the loading axis).

The yield stress of a material is often only known to a certain precision, meaning that there is an uncertainty and therefore a probability distribution associated with the known value.

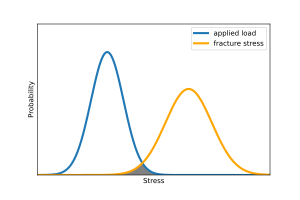

The probability of failure is equivalent to the area between these two distribution functions, mathematically:

or equivalently, if we let the difference between yield stress and applied load equal a third function

The probabilistic design principles allow for precise determination of failure probability, whereas the classical model assumes absolutely no failure before yield strength.

[9] It is clear that the classical applied load vs. yield stress model has limitations, so modeling these variables with a probability distribution to calculate failure probability is a more precise approach.

The probabilistic design approach allows for the determination of material failure under all loading conditions, associating quantitative probabilities to failure chance in place of a definitive yes or no.

In essence, probabilistic design focuses upon the prediction of the effects of variability.

In order to be able to predict and calculate variability associated with model uncertainty, many methods have been devised and utilized across different disciplines to determine theoretical values for parameters such as stress and strain.

Examples of theoretical models used alongside probabilistic design include: Additionally, there are many statistical methods used to quantify and predict the random variability in the desired measurable.

Some methods that are used to predict the random variability of an output include: