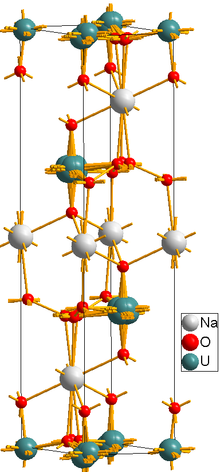

Sodium diuranate

[2] The ratio of the two compounds is determined by process conditions; however, yellowcake is now largely a mix of uranium oxides.

[3] In the classical procedure for extracting uranium, pitchblende is broken up and mixed with sulfuric and nitric acids.

[4] The uranium dissolves to form uranyl sulfate and sodium carbonate is added to precipitate impurities.

[5] The alkaline process of milling uranium ores involves precipitating sodium uranate from the pregnant leaching solution to produce the semi-refined product referred to as yellowcake.

It was also used in porcelain dentures to give them a fluorescence similar to that of natural teeth and once used in pottery to produce ivory to yellow shades in glazes.