Ultimate tensile strength

The ultimate tensile strength of a material is an intensive property; therefore its value does not depend on the size of the test specimen.

Others, which are more ductile, including most metals, experience some plastic deformation and possibly necking before fracture.

Kilopounds per square inch (ksi, or sometimes kpsi) is equal to 1000 psi, and is commonly used in the United States, when measuring tensile strengths.

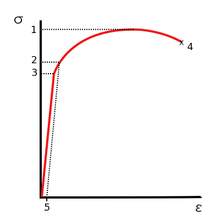

The elastic behavior of materials often extends into a non-linear region, represented in figure 1 by point 2 (the "yield strength"), up to which deformations are completely recoverable upon removal of the load; that is, a specimen loaded elastically in tension will elongate, but will return to its original shape and size when unloaded.

A plastically deformed specimen does not completely return to its original size and shape when unloaded.

[2] Typically, the testing involves taking a small sample with a fixed cross-sectional area, and then pulling it with a tensometer at a constant strain (change in gauge length divided by initial gauge length) rate until the sample breaks.

[3] This practical correlation helps quality assurance in metalworking industries to extend well beyond the laboratory and universal testing machines.

- Ultimate strength

- Yield strength

- Proportional limit stress

- Fracture

- Offset strain (typically 0.2%)

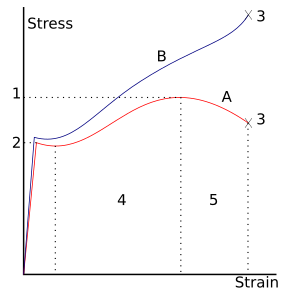

- Ultimate strength

- Yield strength (yield point)

- Rupture

- Strain hardening region

- Necking region

- Apparent stress ( F / A 0 )

- Actual stress ( F / A )