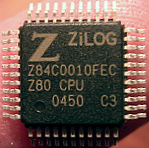

Quad flat package

[2] The QFP component package type became common in Europe and United States during the early nineties, even though it has been used in Japanese consumer electronics since the seventies.

It is often mixed with hole mounted, and sometimes socketed, components on the same printed circuit board (PCB).

A package related to QFP is plastic leaded chip carrier (PLCC) which is similar but has pins with larger pitch, 1.27 mm (or 1/20 inch), curved up underneath a thicker body to simplify socketing (soldering is also possible).

The basic form is a flat rectangular (often square) body with leads on four sides but with numerous variation in the design.

These differ usually only in lead number, pitch, dimensions, and materials used (usually to improve thermal characteristics).

A clear variation is bumpered quad flat package (BQFP) with extensions at the four corners to protect the leads against mechanical damage before the unit is soldered.

A thin quad flat pack (TQFP) provides the same benefits as the metric QFP, but is thinner.

[2] TQFPs help solve issues such as increasing board density, die shrink programs, thin end-product profile and portability.

PQFP, or plastic quad flat pack, is a type of QFP, as is the thinner TQFP package.

Two methods are used in order to make the hermetic sealing: eutectic gold-tin alloy (melting point 280 °C) or seam welding.