Oligonucleotide synthesis

The technique is extremely useful in current laboratory practice because it provides a rapid and inexpensive access to custom-made oligonucleotides of the desired sequence.

The evolution of oligonucleotide synthesis saw four major methods of the formation of internucleosidic linkages and has been reviewed in the literature in great detail.

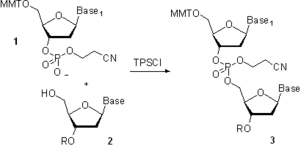

[7][8] The practical implementation of H-phosphonate method resulted in a very short and simple synthetic cycle consisting of only two steps, detritylation and coupling (Scheme 2).

[9] Alternatively, 8 can be converted to phosphorothioate 10[10][11][12][13] or phosphoroselenoate 11 (X = Se),[14] or oxidized by CCl4 in the presence of primary or secondary amines to phosphoramidate analogs 12.

[9][20] In the 1950s, Har Gobind Khorana and co-workers developed a phosphodiester method where 3'-O-acetylnucleoside-5'-O-phosphate 2 (Scheme 3) was activated with N,N'-dicyclohexylcarbodiimide (DCC) or 4-toluenesulfonyl chloride (Ts-Cl).

Following this methodology, sets of tri- and tetradeoxyribonucleotides were synthesized and were enzymatically converted to longer oligonucleotides, which allowed elucidation of the genetic code.

The major limitation of the phosphodiester method consisted in the formation of pyrophosphate oligomers and oligonucleotides branched at the internucleosidic phosphate.

The lack of the convenient protection strategy necessitated taking a retreat to a slower and less selective chemistry to achieve the ultimate goal of the study.

The higher selectivity of the method allowed the use of more efficient coupling agents and catalysts,[24][25] which dramatically reduced the length of the synthesis.

The method, initially developed for the solution-phase synthesis, was also implemented on low-cross-linked "popcorn" polystyrene,[26] and later on controlled pore glass (CPG, see "Solid support material" below), which initiated a massive research effort in solid-phase synthesis of oligonucleotides and eventually led to the automation of the oligonucleotide chain assembly.

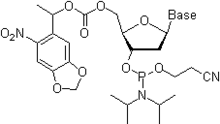

[1] As mentioned above, the naturally occurring nucleotides (nucleoside-3'- or 5'-phosphates) and their phosphodiester analogs are insufficiently reactive to afford an expeditious synthetic preparation of oligonucleotides in high yields.

[63] Oligonucleotide synthesis is carried out by a stepwise addition of nucleotide residues to the 5'-terminus of the growing chain until the desired sequence is assembled.

The orange-colored DMT cation formed is washed out; the step results in the solid support-bound oligonucleotide precursor bearing a free 5'-terminal hydroxyl group.

It is worth remembering that conducting detritylation for an extended time or with stronger than recommended solutions of acids leads to depurination of solid support-bound oligonucleotide and thus reduces the yield of the desired full-length product.

[68] The mixing is usually very brief and occurs in fluid lines of oligonucleotide synthesizers (see below) while the components are being delivered to the reactors containing solid support.

The capping step is performed by treating the solid support-bound material with a mixture of acetic anhydride and 1-methylimidazole or, less often, DMAP as catalysts and, in the phosphoramidite method, serves two purposes.

The newly formed tricoordinated phosphite triester linkage is not natural and is of limited stability under the conditions of oligonucleotide synthesis.

In a simple case of a dinucleotide, this results in the formation of a diastereomeric pair of Sp- and Rp-dinucleoside monophosphorothioates whose structures are shown in Figure.

This property determines the use of OPS as antisense oligonucleotides in in vitro and in vivo applications where the extensive exposure to nucleases is inevitable.

Of many reported reagents capable of the efficient sulfur transfer, only three are commercially available: In the past, oligonucleotide synthesis was carried out manually in solution or on solid phase.

[102] Multi-well plate format is designed specifically for high-throughput synthesis on small scale to satisfy the growing demand of industry and academia for synthetic oligonucleotides.

This platform was originally designed as a peptide synthesizer and made use of a fluidized bed reactor essential for accommodating the swelling characteristics of polystyrene supports used in the Merrifield methodology.

Oligonucleotide synthesis involved the use of CPG (controlled pore glass) which is a rigid support and is more suited for column reactors as described above.

Some novel reactor designs as well as higher than normal pressures enabled the 8800 to achieve scales that would prepare 1 mmol of oligonucleotide.

[106] One may visualize an oligonucleotide microarray as a miniature multi-well plate where physical dividers between the wells (plastic walls) are intentionally removed.

Under the strong basic conditions required for the removal of N-acyl protection, acrylonitrile is capable of alkylation of nucleic bases, primarily, at the N3-position of thymine and uracil residues to give the respective N3-(2-cyanoethyl) adducts via Michael reaction.