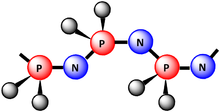

Polyphosphazene

[1][2][3][4] In the first step, hexachlorocyclotriphosphazene(NPCl2)3 is heated in a sealed system at 250 °C to convert it to a long chain linear polymer with typically 15,000 or more repeating units.

In the second step the chlorine atoms linked to phosphorus in the polymer are replaced by organic groups through reactions with alkoxides, aryloxides, amines or organometallic reagents.

[10][11][12][13] Cyclomatrix type polymers made by linking small molecule phosphazene rings together employ difunctional organic reagents to replace the chlorine atoms in (NPCl2)3, or the introduction of allyl or vinyl substituents, which are then polymerized by free-radical methods.

The first stable thermoplastic poly(organophosphazenes), isolated in the mid 1960s by Allcock, Kugel, and Valan, were macromolecules with trifluoroethoxy, phenoxy, methoxy, ethoxy, or various amino side groups.

[2][3][4] Of these early species, poly[bis(trifluoroethoxyphosphazene], [NP(OCH2CF3)2]n, has proved to be the subject of intense research due to its crystallinity, high hydrophobicity, biological compatibility, fire resistance, general radiation stability, and ease of fabrication into films, microfibers and nanofibers.

The first large-scale commercial uses for linear polyphosphazenes were in the field of high technology elastomers, with a typical example containing a combination of trifluoroethoxy and longer chain fluoroalkoxy groups.

Glass transition temperatures as low as -60 °C are attainable, and properties such as oil-resistance and hydrophobicity are responsible for their utility in land vehicles and aerospace components.

[19] Other side groups, such as non-fluorinated alkoxy or oligo-alkyl ether units, yield hydrophilic or hydrophobic elastomers with glass transitions over a broad range from -100 °C to 100 °C.

[27] The ease with which properties can be controlled and fine-tuned by the linkage of different side groups to polyphosphazene chains has prompted major efforts to address biomedical materials challenges using these polymers.

Nanofibers and porous constructs of these polymers assist osteoblast replication and accelerate the repair of bone in animal model studies.

The patent literature contains many references to cyclomatrix polymers derived from cyclic trimeric phosphazenes incorporated into cross-linked resins for fire resistant circuit boards and related applications.