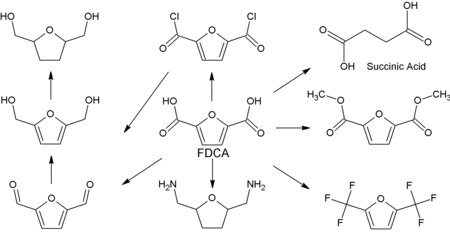

2,5-Furandicarboxylic acid

[2] It can be produced from certain carbohydrates and as such is a renewable resource, it was identified by the US Department of Energy as one of 12 priority chemicals for establishing the “green” chemistry industry of the future.

This reaction requires severe conditions (highly concentrated acids, temp > 120 °C, React time > 20h) and all the methods were non-selective with yields < 50%.

Oxidation of HMF under strongly alkaline conditions over noble metal catalysts gives almost quantitative formation of FDCA.

[12] Also, the direct, one pot dehydration and oxidation of fructose to FDCA via intermediate HMF has been investigated with good selectivities, unfortunately this system does not work in water.

Andrisano reported that potassium 2-furoate, when heated up to 300 °C in a nitrogen atmosphere, underwent decarboxylation to furan with simultaneous carboxylation at position 5 to di-potassium 2,5-furandicarboxylate.

Numerous studies were undertaken to establish the metabolism of this compound and to determine the quantity, which is produced depending on the healthiness of the human.

A Pseudomonas putida strain that was genetically engineered to express this enzyme can completely and selectively convert HMF to FDCA.

This biocatalysis is performed in water, at ambient temperature and pressure, without toxic or polluting chemicals, making it very environmentally friendly.

For example, PEF is only a member of the vast poly(alkylene 2,5-furandicarboxylate) family, in which FDCA is combined with diols of variable alkyl chain length (containing up to 12 methyl groups).

The diacid itself is a strong complexing agent, chelating such ions as: Ca2+, Cu2+ and Pb2+; it is utilized in medicine to remove kidney stones.

[26] The primary technical barrier in the production and use of FDCA is the development of an effective and selective dehydration process from sugars.

The control of sugar dehydration could be a very powerful technology, leading to a wide range of additional, inexpensive building blocks, but it is not yet well understood.

FDCA formation will require development of cost-effective and industrially viable oxidation technology that can operate in concert with the necessary dehydration processes.