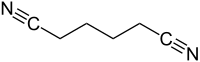

Adiponitrile

After patent application in 2004, the majority of adiponitrile is prepared by the nickel-catalysed hydrocyanation of butadiene, as discovered at DuPont, pioneered by William C. Drinkard.

In the final stage, these pentenenitriles are subjected to a second hydrocyanation to produce adiponitrile,[4] the anti-Markovnikov product, as well as 2-methylglutaronitrile, a useful byproduct.

Another side reaction is the alkene metathesis of 3-pentenenitrile to yield dicyanobutenes, which are readily hydrogenated to adiponitrile as described above.

[citation needed] The main producers of adiponitrile were:[8][9] BASF closed the 128 kt/y ADN plant at Seal Sands in 2009.

[12] The NIOSH recommended skin exposure limit for a work-related time weighted average concentration is 4ppm (18 mg/m3).