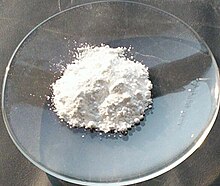

Zinc oxide

ZnO is used as an additive in numerous materials and products including cosmetics, food supplements, rubbers, plastics, ceramics, glass, cement, lubricants,[12] paints, sunscreens, ointments, adhesives, sealants, pigments, foods, batteries, ferrites, fire retardants, semi conductors,[13] and first-aid tapes.

[14] Early humans probably used zinc compounds in processed[14] and unprocessed forms, as paint or medicinal ointment; however, their composition is uncertain.

The use of pushpanjan, probably zinc oxide, as a salve for eyes and open wounds is mentioned in the Indian medical text the Charaka Samhita, thought to date from 500 BC or before.

[21] Around 1782, Louis-Bernard Guyton de Morveau proposed replacing lead white pigment with zinc oxide.

In 1845, Edme-Jean Leclaire in Paris was producing the oil paint on a large scale; by 1850, zinc white was being manufactured throughout Europe.

However, in nature, it occurs as the rare mineral zincite, which usually contains manganese and other impurities that confer a yellow to red color.

This property accounts for the preferential formation of wurtzite rather than zinc blende structure,[36] as well as the strong piezoelectricity of ZnO.

[41] Favourable properties of zinc oxide include good transparency, high electron mobility, wide band gap, and strong room-temperature luminescence.

Those properties make ZnO valuable for a variety of emerging applications: transparent electrodes in liquid crystal displays,[42] energy-saving or heat-protecting windows,[25] and electronics as thin-film transistors and light-emitting diodes.

Advantages associated with a wide band gap include higher breakdown voltages, ability to sustain large electric fields, lower electronic noise, and high-temperature and high-power operation.

[13] Due to this large band gap, there have been efforts to create visibly transparent solar cells utilising ZnO as a light absorbing layer.

Zinc vapor reacts with the oxygen in the air to give ZnO,[54] accompanied by a drop in its temperature and bright luminescence.

[citation needed] Numerous specialised methods exist for producing ZnO for scientific studies and niche applications.

[citation needed] Large single crystals (many cubic centimeters) can be grown by the gas transport (vapor-phase deposition), hydrothermal synthesis,[37][55][56] or melt growth.

[61] Nanostructures of ZnO can be synthesized into a variety of morphologies, including nanowires, nanorods, tetrapods, nanobelts, nanoflowers, nanoparticles, etc.

[37][62][63] The synthesis is typically carried out at temperatures of about 90 °C, in an equimolar aqueous solution of zinc nitrate and hexamine, the latter providing the basic environment.

[65] The morphology of the resulting nanostructures can be tuned by changing the parameters relating to the precursor composition (such as the zinc concentration and pH) or to the thermal treatment (such as the temperature and heating rate).

Consequently, it is added into materials and products including plastics, ceramics, glass, cement,[72] rubber, lubricants,[12] paints, ointments, adhesive, sealants, concrete manufacturing, pigments, foods, batteries, ferrites, and fire retardants.

Zinc oxide as a low expansion, secondary flux improves the elasticity of glazes by reducing the change in viscosity as a function of temperature and helps prevent crazing and shivering.

[99] The mechanism of ZnO's antibacterial effect has been variously described as the generation of reactive oxygen species, the release of Zn2+ ions, and a general disturbance of the bacterial cell membrane by nanoparticles.

[82] It is the broadest spectrum UVA and UVB absorber[101][102] that is approved for use as a sunscreen by the U.S. Food and Drug Administration (FDA),[103] and is completely photostable.

Zinc oxide and the other most common physical sunscreen, titanium dioxide, are considered to be nonirritating, nonallergenic, and non-comedogenic.

[125] Some optoelectronic applications of ZnO overlap with that of GaN, which has a similar band gap (~3.4 eV at room temperature).

[126] Other properties of ZnO favorable for electronic applications include its stability to high-energy radiation and its ability to be patterned by wet chemical etching.

Nanostructured ZnO is an effective medium both in powder and polycrystalline forms in random lasers,[129] due to its high refractive index and aforementioned light emission properties.

It is formed into nanostructures such as thin films, nanoparticles, nanopillars, or nanowires to provide a large surface area for interaction with gasses.

[134] The piezoelectricity in textile fibers coated in ZnO have been shown capable of fabricating "self-powered nanosystems" with everyday mechanical stress from wind or body movements.

[135][136] ZnO, both in macro-[137] and nano-[138] scales, could in principle be used as an electrode in photocatalysis, mainly as an anode[139] in green chemistry applications.

As a photocatalyst, ZnO reacts when exposed to UV radiation[137] and is used in photodegradation reactions to remove organic pollutants from the environment.

[146] Inhalation of zinc oxide, which may occur when welding galvanized (zinc-plated) steel, can result in a malady called metal fume fever.