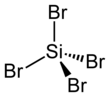

Silicon tetrabromide

Covalently saturated silicon complexes like SiBr4, along with tetrahalides of germanium (Ge) and tin (Sn), are Lewis acids.

[9] It can also be produced by treating silicon-copper mixture with bromine:[10] Like other halosilanes, SiBr4 can be converted to hydrides, alkoxides, amides, and alkyls, i.e., products with the following functional groups: Si-H, Si-OR, Si-NR2, Si-R, and Si-X bonds respectively.

[3] Redistribution reactions occur between two different silicon tetrahalides (as well as halogenated polysilanes) when heated to 100 ˚C, resulting in various mixed halosilanes.

The pyrolysis of SiBr4 does have the advantage of depositing silicon at faster rates than that of SiCl4, however SiCl4 is usually preferred due to its availability in high purity.

[13] Pyrolysis of SiBr4 followed by treatment with ammonia yields silicon nitride (Si3N4) coatings, a hard compound used for ceramics, sealants, and the production of many cutting tools.